Contact Details

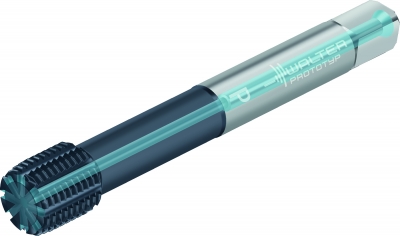

Walter has introduced the TC430 Supreme thread former for steel, offering maximum tool life in all formable steel materials, plus high surface quality on the thread, and a high level of process stability since no chips are formed and the tool cross section is stable.

The TC430 Supreme thread former, specialized for ISO P materials, is for blind-hole and through-hole threads up to 3.5 x DN. Multiple coolant configurations are offered to best optimize performance—axial or radial coolant, with or without lubrication grooves. This HSS-E-PM thread former with AlCrN or TiN coating is available for both metric and metric fine threads. Grade designations are WW60AD andWW60EL.

The tool has a high number of forming edges and its extremely smooth AlCrN coating minimizes weld formations in materials with high adhesion. It features tolerances of 6HX and 6GX, with dimensions of M2 to M20 metric, and metric fine of M8 x 1-M16 x 1.5. The Walter TC430 Supreme is finding ready acceptance in general metalworking as well as the automotive and energy industries.

The Walter lineup of products consists of three categories to its tools. Supreme indicates the highest level of technology and performance available. Perform tools are products that provide an economical solution with focused importance on price and Advance which indicates product efficiently balanced between price and performance.

Related Glossary Terms

- blind-hole

blind-hole

Hole or cavity cut in a solid shape that does not connect with other holes or exit through the workpiece.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- metalworking

metalworking

Any manufacturing process in which metal is processed or machined such that the workpiece is given a new shape. Broadly defined, the term includes processes such as design and layout, heat-treating, material handling and inspection.

- through-hole

through-hole

Hole or cavity cut in a solid shape that connects with other holes or extends all the way through the workpiece.

- titanium nitride ( TiN)

titanium nitride ( TiN)

Added to titanium-carbide tooling to permit machining of hard metals at high speeds. Also used as a tool coating. See coated tools.

PRODUCTS

PRODUCTS