Contact Details

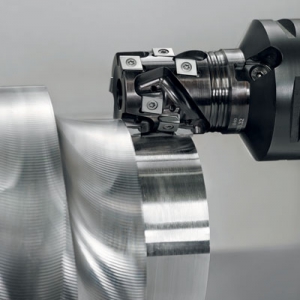

Walter has announced the Walter TC630 Supreme solid carbide orbital thread milling cutter for blind-hole and through-hole threads, with new DeVibe technology. Unstable conditions and long overhangs often lead to vibration, poor thread surfaces or even fractures during thread milling. The patent pending DeVibe anti-vibration technology, which includes an anti-vibration land on the flank face, the TC630 is supported during machining, suppressing vibration.

DeVibe technology ensures excellent operational smoothness and enables usable lengths up to 4×DN. It is ideal for small threads, long overhangs, unstable conditions or difficult materials. One reason for this is the geometry: Since only one row of cutting edges is engaged at a time, the tool deflection is low, and the thread remains cylindrical. The moderate number of teeth also enables a high feed per tooth, minimizing wear.

The milling cutter for blind-hole and through-hole threads can be used universally: In all ISO materials up to 48 HRC and for all dimensions from M1.6 to M20. In addition, it is suitable for tools for metric fine-pitch threads, UNC, UNF and STI UNF, the latter primarily for the aerospace sector.

With the TC630 Supreme, users can benefit from a range of advantages. A high level of process reliability for unstable machining operations, for example on lathes with driven tools or for long overhangs. Areas of application include medical engineering, precision engineering, the aerospace sector as well as electronics and general metalworking.

The Walter lineup of products consists of three categories to its tools. Supreme indicates the highest level of technology and performance available. Perform tools are products that provide an economical solution with focused importance on price and Advance which indicates product efficiently balanced between price and performance.

Related Glossary Terms

- blind-hole

blind-hole

Hole or cavity cut in a solid shape that does not connect with other holes or exit through the workpiece.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- land

land

Part of the tool body that remains after the flutes are cut.

- metalworking

metalworking

Any manufacturing process in which metal is processed or machined such that the workpiece is given a new shape. Broadly defined, the term includes processes such as design and layout, heat-treating, material handling and inspection.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling cutter

milling cutter

Loosely, any milling tool. Horizontal cutters take the form of plain milling cutters, plain spiral-tooth cutters, helical cutters, side-milling cutters, staggered-tooth side-milling cutters, facemilling cutters, angular cutters, double-angle cutters, convex and concave form-milling cutters, straddle-sprocket cutters, spur-gear cutters, corner-rounding cutters and slitting saws. Vertical cutters use shank-mounted cutting tools, including endmills, T-slot cutters, Woodruff keyseat cutters and dovetail cutters; these may also be used on horizontal mills. See milling.

- through-hole

through-hole

Hole or cavity cut in a solid shape that connects with other holes or extends all the way through the workpiece.

PRODUCTS

PRODUCTS