TENDO Platinum Toolholder

TENDO Platinum Toolholder

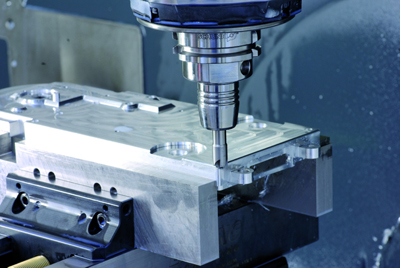

SCHUNK introduces the TENDO Platinum toolholder.

SCHUNK introduces the TENDO Platinum toolholder. TENDO Platinum boasts improved brazing technology by using a unique brazing and hardening process all in the same cycle, allowing for a rigid and durable tool clamping.

TENDO Platinum is manufactured from tool steel and through-hardened to ensure long life. The TENDO Platinum is balanced to G2.5 at 25,000 RPM. With vibration dampening and precise run out accuracy of less than 0.003mm (0.0001") at 2.5 times the clamping diameter, the TENDO Platinum protects the machine spindle and the cutting tool from wear and damage.

SCHUNK offers three lengths with two precision ground taper sized: CAT 40 2.5", 4", 6" and CAT 50 81mm, 4", 6".