Contact Details

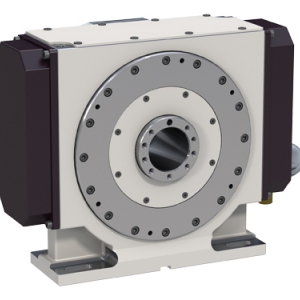

Koma Precision Inc. has introduced the new TH Line angle heads from Alberti. The TH line of angle heads is targeted for aerospace parts manufacturing. The angle head casting is made from GS 600 stabilized spheroidal cast iron that enables the tool to perform optimally. The GS 600 alloy provides increased thermal stability and rigidity compared to materials such as steel and aluminum.

The most important feature of this line is that the TH Series angle heads can be run with or without coolant, without making any changes to the installation. The offset design of the TH Series heads enables customers to use extended length tools.

All Alberti angle head spindles with arbor are manufactured from one solid piece of hardened steel that increases resistance to bending stress by 25 percent. This also enables the tools reach higher RPM without vibrations, thus resulting in higher speed and precision. The unique angular contact bearings ensure concentricity and stability required to achieve higher performance of machining operations. The mechanical seals and gears are researched and developed at the Alberti Engineering and Technology Center.

Related Glossary Terms

- arbor

arbor

Shaft used for rotary support in machining applications. In grinding, the spindle for mounting the wheel; in milling and other cutting operations, the shaft for mounting the cutter.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

PRODUCTS

PRODUCTS