ThermoComp is a Mechatronic Solution to Thermal Errors

ThermoComp is a Mechatronic Solution to Thermal Errors

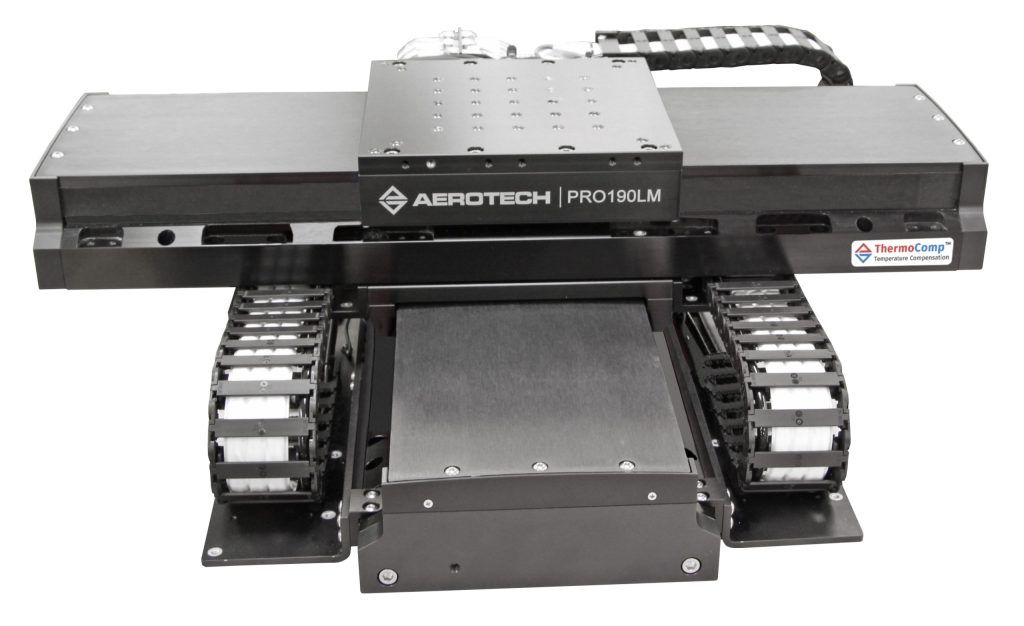

Aerotech says its new product feature, ThermoComp, is a complete mechatronic solution to thermal errors. Through the employment of integrated hardware and sensors, and a proprietary compensation algorithm implemented via Aerotech's A3200 controller software, ThermoComp minimizes stage inaccuracy due to thermal effects even over extreme temperature ranges.

Temperature changes and thermal effects are some of the largest error sources in precision machines. One major reason for this is the difficulty and often extreme expense associated with designing a thermally insensitive machine.

The most frequent approach to reducing thermal errors is to regulate the environment in which the machine operates. This mitigates the need to design a thermally insensitive machine, which is a difficult and costly endeavor. Although successful at minimizing thermal effects, environmental regulation can also be expensive when maintaining precise building temperature control, and always adds to production quality risks due to the inherently unreliable stability of most air-conditioning systems. The level of environmental stability achieved in most industrial facilities (normally on the order of 1°C) can be wholly inadequate for many high-precision manufacturing processes.

Aerotech says its new product feature, ThermoComp, is a complete mechatronic solution to thermal errors. Through the employment of integrated hardware and sensors, and a proprietary compensation algorithm implemented via Aerotech's A3200 controller software, ThermoComp minimizes stage inaccuracy due to thermal effects even over extreme temperature ranges. Up to 90 percent of the thermal-related errors can be eliminated, regardless of stage travel and range of temperature change.

Additionally, internal self-heating is another major source of thermal-related positioning errors, particularly in stages without direct feedback devices such as ball-screw-driven stages. ThermoComp not only prevents environmental changes from affecting positioning performance, but also diminishes the errors caused through internal heating, eliminating up to 90 percent of the thermal-related errors caused by the self-heating of a ballscrew-driven stage.

ThermoComp is available on all Aerotech PRO Series stages and operates through an intuitive and easy-to-use integrated command set within the Aerotech A3200 controller software.