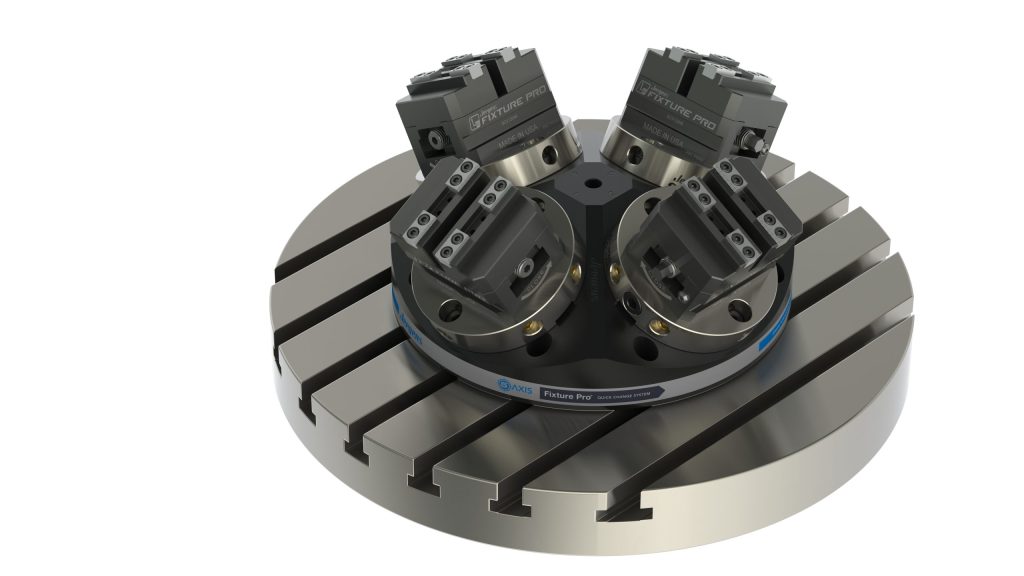

Three- and Four-Sided Pyramid Risers

Three- and Four-Sided Pyramid Risers

The engineered solutions offer three versatile mounting options. Direct-to-table uses t-slots, center pin and timing key, and is secured using t nuts and Socket Head Cap Screws (SHCS). QLS accurately locates and clamps the pyramid to a base element, such as subplates, using a combination of QLS shoulder screws and SHCS. Quick-Loc™ pallet systems use pull studs (spaced at the industry-standard 96mm pattern) to locate and clamp in a single step.

Jergens Inc. announces its new three- and four-sided pyramid risers that permit multi part load and provide greater access for five axis machining applications. Part of the Fixture-Pro® line of quick-change modular workholding solutions, Jergens pyramids feature a 30-degree mounting surface to ensure maximum clearance for spindle and cutting tool paths resulting in more machining per setup

The engineered solutions offer three versatile mounting options. Direct-to-table uses t-slots, center pin and timing key, and is secured using t nuts and Socket Head Cap Screws (SHCS). QLS accurately locates and clamps the pyramid to a base element, such as subplates, using a combination of QLS shoulder screws and SHCS. Quick-Loc™ pallet systems use pull studs (spaced at the industry-standard 96mm pattern) to locate and clamp in a single step.

The light-weight aluminum risers are compatible with virtually all five axis CNC machining centers and ensure the fastest change over and setup times possible. Available in both three-position and four-position configurations, Jergens pyramid risers mate with many top tooling choices including self-centering vises, dovetail vises and ER collet fixtures.