Contact Details

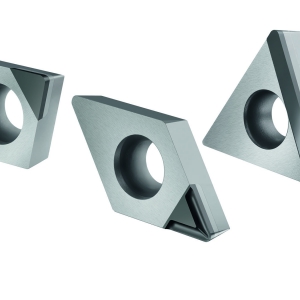

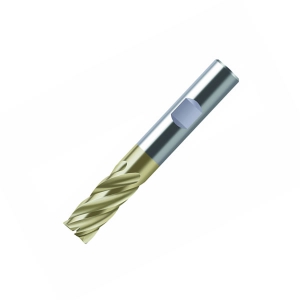

Walter has announced several extensions to its Tiger-tec Gold inserts, all of which possess the features that have made it so successful: A smooth rake face for excellent friction characteristics; optimal wear detection due to its gold-colored top layer; an especially tough cutting edge for maximum process reliability; and the latest coating technology for long tool life.

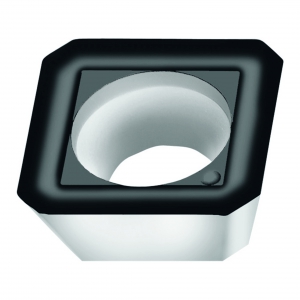

The extensions of the Tiger-tec Gold line include the new WKP35G milling grade, manufactured using the ultralow-pressure CVD method (ULP-CVD), and available in both positive and negative inserts. Sintered inserts for the Walter BLAXX shoulder milling cutters with four 90° cutting edges. M4000 extensions with a square shape, wavy design of the clearance face and small corner radii. Tough sintered inserts for the F4045 cutter with 14 cutting edges and variant corner radius. Also, a new wiper insert for the F4045. New inserts for the M3024 boasting 14 cutting edges, positive geometry, and secondary cutting edge or corner radius. And two new wiper inseGrts for the M2136 shoulder mill.

Like previous Tiger·tec Gold inserts, the extensions to the line employ a particularly tough carbide substrate covered by an extremely tough and resistant TiAIN layer with a high aluminum content and topped by a TiN top layer that helps protect the substrate against abrasion, hairline cracks, plastic deformation and oxidation. This gold-colored top layer enables outstanding wear detection and boasts impressive friction characteristics. Additionally, a thin TiN layer is located between the carbide substrate and the TiAIN layer, ensuring excellent binding of the layers.

Related Glossary Terms

- chemical vapor deposition ( CVD)

chemical vapor deposition ( CVD)

High-temperature (1,000° C or higher), atmosphere-controlled process in which a chemical reaction is induced for the purpose of depositing a coating 2µm to 12µm thick on a tool’s surface. See coated tools; PVD, physical vapor deposition.

- clearance

clearance

Space provided behind a tool’s land or relief to prevent rubbing and subsequent premature deterioration of the tool. See land; relief.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling machine ( mill)

milling machine ( mill)

Runs endmills and arbor-mounted milling cutters. Features include a head with a spindle that drives the cutters; a column, knee and table that provide motion in the three Cartesian axes; and a base that supports the components and houses the cutting-fluid pump and reservoir. The work is mounted on the table and fed into the rotating cutter or endmill to accomplish the milling steps; vertical milling machines also feed endmills into the work by means of a spindle-mounted quill. Models range from small manual machines to big bed-type and duplex mills. All take one of three basic forms: vertical, horizontal or convertible horizontal/vertical. Vertical machines may be knee-type (the table is mounted on a knee that can be elevated) or bed-type (the table is securely supported and only moves horizontally). In general, horizontal machines are bigger and more powerful, while vertical machines are lighter but more versatile and easier to set up and operate.

- plastic deformation

plastic deformation

Permanent (inelastic) distortion of metals under applied stresses that strain the material beyond its elastic limit.

- rake

rake

Angle of inclination between the face of the cutting tool and the workpiece. If the face of the tool lies in a plane through the axis of the workpiece, the tool is said to have a neutral, or zero, rake. If the inclination of the tool face makes the cutting edge more acute than when the rake angle is zero, the rake is positive. If the inclination of the tool face makes the cutting edge less acute or more blunt than when the rake angle is zero, the rake is negative.

- titanium nitride ( TiN)

titanium nitride ( TiN)

Added to titanium-carbide tooling to permit machining of hard metals at high speeds. Also used as a tool coating. See coated tools.

- wiper

wiper

Metal-removing edge on the face of a cutter that travels in a plane perpendicular to the axis. It is the edge that sweeps the machined surface. The flat should be as wide as the feed per revolution of the cutter. This allows any given insert to wipe the entire workpiece surface and impart a fine surface finish at a high feed rate.

PRODUCTS

PRODUCTS