Contact Details

September 01, 2010

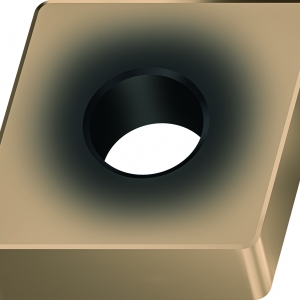

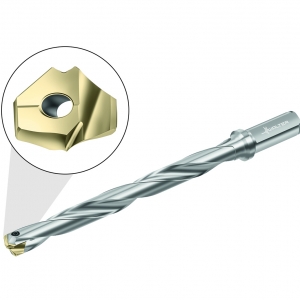

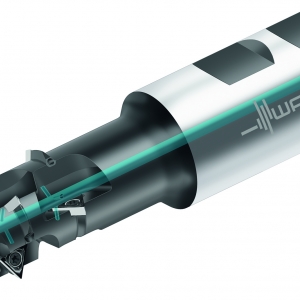

Walter USA LLC reports that its Tiger-tec Silver CVD-coated cutting tool material offers extreme toughness for high thermal shock resistance and enhanced wear characteristics at high machining temperatures. According to the company, tool material properties can be adjusted in such a way as to improve cracking and breaking sensitivity, without having a negative impact on the high-temperature characteristics.

PRODUCTS

PRODUCTS