Contact Details

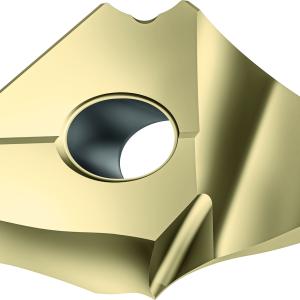

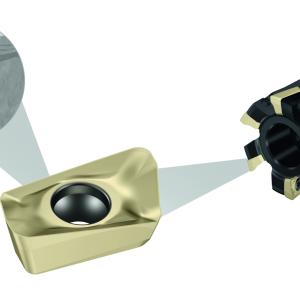

Walter has introduced Tiger-tec Silver HU6, a round insert with a new geometry, specifically developed for medium and heavy-duty roughing of solid railroad wheels and other forged parts. Large chip build-up is a common problem particularly when turning the inner profile of a railroad wheel, with the chips often failing to break as desired. Productivity and tool life both suffer as a result. Tiger-tec Silver HU6 was developed to address these chip control problems, and field tests at wheel manufacturers have shown that this new Walter insert provides up to 40 percent longer tool life.

The key innovation is the insert's geometry, featuring specially formed chip dimples for ideal chip formation, facilitating chip breaking in the required area. This new round insert benefits from Walter's Tiger-tec Silver coating which enhances cutting speed, reliability and tool life. The inserts are available in four different grades: three for steel and one for cast iron machining. Insert diameter selection ranges from 10 to 32mm. This combination of coating and geometry, with its specially designed chip breaker and strong cutting edge for process reliability in heavy and interrupted cuts, boosts the productivity of heavy-duty roughing operations, such as railway vehicle manufacturing, generator and turbine manufacturing, and forged components in general.

In addition, Walter Capto turning toolholders can be used with the HU6. This interface enables quick tool changes and easily handles the transfer of large forces.

Related Glossary Terms

- cutting speed

cutting speed

Tangential velocity on the surface of the tool or workpiece at the cutting interface. The formula for cutting speed (sfm) is tool diameter 5 0.26 5 spindle speed (rpm). The formula for feed per tooth (fpt) is table feed (ipm)/number of flutes/spindle speed (rpm). The formula for spindle speed (rpm) is cutting speed (sfm) 5 3.82/tool diameter. The formula for table feed (ipm) is feed per tooth (ftp) 5 number of tool flutes 5 spindle speed (rpm).

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

PRODUCTS

PRODUCTS