Contact Details

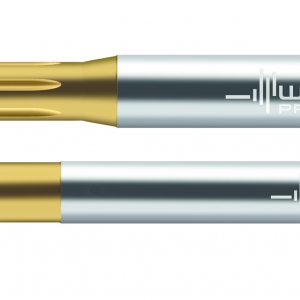

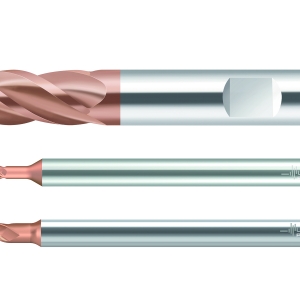

Walter USA LLC has introduced the Walter Titex X-treme Inox, a high performance solid carbide drill with internal coolant and special coating, designed to tackle stainless steel and other high-alloy ISO M materials.

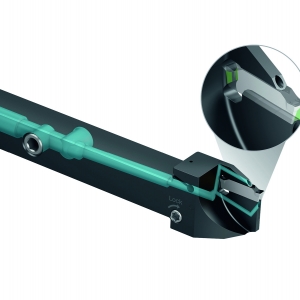

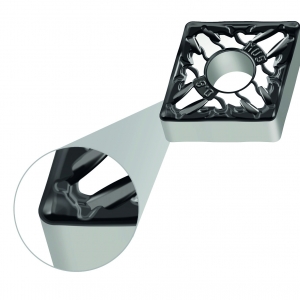

The X-treme Inox advantage begins with a tip geometry that has been specially adapted to these materials, reducing the cutting forces and minimizing the otherwise frequent formation of burrs. A multilayer TiAlN tip coating maximizes tool life while minimizing adhesion. A high degree of process stability is ensured thanks to the superior stability of the X-treme Inox's main cutting edges, and the drill's new flute profile. The coordinated margins ensure minimal friction against the hole wall, while correct operating temperature is made possible through the internal coolant supply characteristic of the universal drills in the X-treme series.

These properties and features work together to produce excellent hole quality when drilling stainless steel, along with a high degree of process reliability and feed rates up to 50 percent higher than those obtained with other universal solid carbide drilling tools.

Walter supplies the Walter Titex X-treme Inox drill in diameter ranges 1⁄8 to ¾ inch and 3-20mm, and in standard lengths up to 5xD. Additional lengths of up to 12xD and stepped tools are optional. Typical applications for the Walter Titex X-treme Inox drill can be found in the aerospace, chemical, and medical device industries, as well as in the production of food processing equipment and in general metalworking.

Related Glossary Terms

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- metalworking

metalworking

Any manufacturing process in which metal is processed or machined such that the workpiece is given a new shape. Broadly defined, the term includes processes such as design and layout, heat-treating, material handling and inspection.

- titanium aluminum nitride ( TiAlN)

titanium aluminum nitride ( TiAlN)

Often used as a tool coating. AlTiN indicates the aluminum content is greater than the titanium. See coated tools.

PRODUCTS

PRODUCTS