Tool ID Software

Tool ID Software

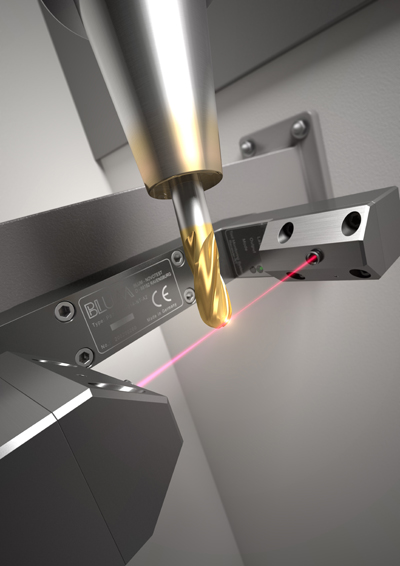

Blum-Novotest Inc. unveils the release of its new Tool ID (Tool Identification) software package, designed to act as a cost effective alternative for automating the monitoring of tooling and tooling condition when integrated with an existing Blum laser tool setter.

Blum-Novotest Inc. unveils the release of its new Tool ID (Tool Identification) software package, designed to act as a cost effective alternative for automating the monitoring of tooling and tooling condition when integrated with an existing Blum laser tool setter.

Many manufacturers have adapted a methodology of using a CAD/CAM software application for posting their part/job data. Under this methodology, both optimal tool dimensions and tool path data are created in the CAD/CAM software application. This data is then exported so it can be loaded directly into the CNC and a corresponding tool list is created. The operator then uses this tool list to load the required tools for the job into the tool changer. But what happens if an operator reads the tool list incorrectly or simply inserts the wrong tool into a tool pod without noticing? The difference between a ball nose and bull nose cutter can sometimes be so small it is easily unnoticed. The operator may then use the wrong tools to cut the part, or multiple parts, and unknowingly produce scrap.

To solve this problem, many manufacturers are typically told of conventional RFID systems that can be integrated into their tooling. The required tools are prepared on a tool presetter, the tool dimensions are stored within the RFID chip which is then read when inserted into the machining center. The problem with such solutions is that they are extremely expensive and require long lead times for implementation, usually deterring customers from following through.

Tool ID software offers an alternate, more cost effective solution by using macro-programming with Blum's laser tool setter. Tool ID is simply installed on the CNC and can either be access by the operator on the NC screen or tied directly to a one-button start for automation. Once the required tools are loaded into the machine, the operator can execute the program which will automatically access the laser's programming and measure all tools listed in the job. The laser first identifies all tool dimensions and Tool ID then uses logic statements to verify that the measurements match those of the tool data that was loaded into the control memory. If measurements differ by a user-definable degree, the operator will receive an error message. This alerts the operator to incorrectly inserted tools, tools worn past a safe limit, and even broken tools. Using Blum's LaserControl NT tool setter and the Tool ID logic, the two are able to automatically identify over 90 percent of a commonly used tools.

With Tool ID, you get the benefit of minimized risk through a now more tightly controlled and automated process, along with all the benefits and accuracy that come with using the Blum LaserControl NT system, and all at a fraction of the cost of an RFID package.