Toolinspect Embedded Computer System

Toolinspect Embedded Computer System

Toolinspect from MCU GmbH & Co. KG is a CNC machining process monitoring system that's data driven from NCU/PLC and collected from the drives to allow for the most sensitive tool monitoring and collecting process data for process analysis.

Toolinspect from MCU GmbH & Co. KG is a CNC machining process monitoring system that's data driven from NCU/PLC and collected from the drives to allow for the most sensitive tool monitoring and collecting process data for process analysis.

Toolinspect is an embedded computer system, integrated as a slave in a field bus system (Profibus-DP, Profinet-PN or MOD-Bus). It is a real time, algorithm driven system that operates self-adjusting from the initial cut.

It is the lowest service system for tool and process monitoring, simple to install and when installed ready to use. Its 3 button operation makes it simple for the operator, with much data available for the technician to optimize the process.

The integration into the PLC/NCU allow Toolinspect to freely adjust to the best monitoring strategy based on tool and machining information, recognizes program changes, incorrect tool changes and incorrect placed parts in the machine. Small adjustments if necessary can be made in the NC program.

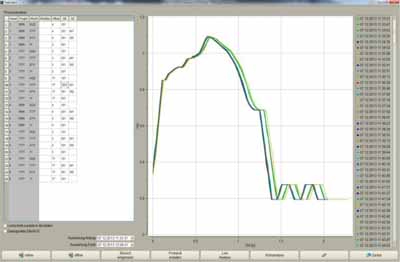

The system can operate in up to 6 channels, each channel monitors 3 data streams from spindle and/or axis and is set to either change values in all channels, selected channels or a single tool only.

The visualization can be implemented on different platforms, such as Windows, Linux or Android, and Toolinspect is compatible with the Controls from BoschRexroth, FANUC, HEIDENHAIN, Siemens 840D/840Dsl/828D and others.