TraceBoss Software

TraceBoss Software

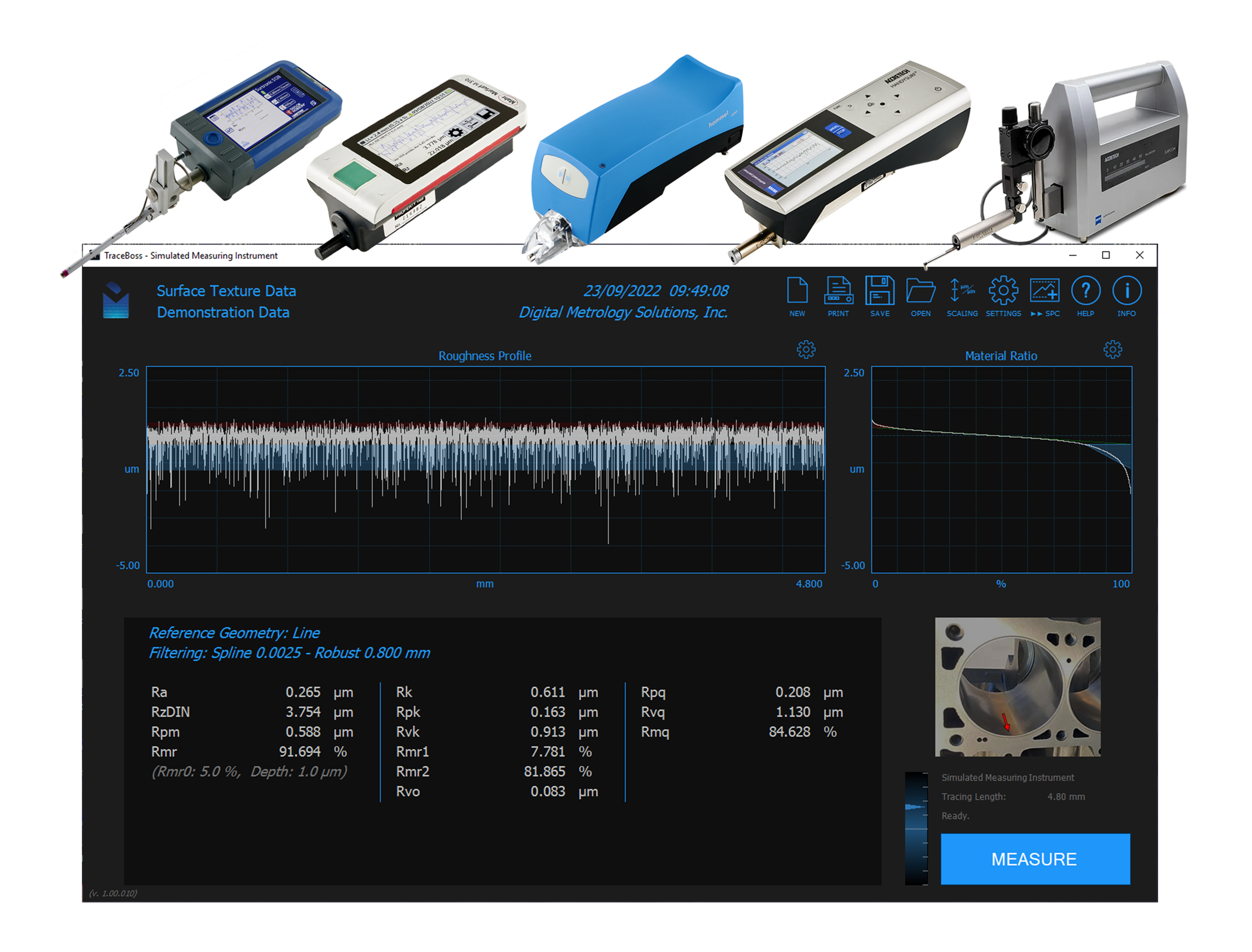

The TraceBoss software interfaces with most portable surface roughness gages via a USB connection. One click in TraceBoss configures the gage, initiates a measurement, and presents the results and graphics full screen and in high resolution. The software display is optimized for the highest visibility in shop environments.

Digital Metrology Solutions, provider of measurement software, consulting, and training, has introduced the TraceBoss software package for portable roughness gages.

"Most portable gages show you a roughness number or two and perhaps a small image of a profile on a tiny screen," says Mark Malburg, President of Digital Metrology Solutions. "As a result, many users are eager to do more with their data. TraceBoss gives portable gage users the power of a high-end instrument at a far lower price, and in an easy-to- use package."

The TraceBoss software interfaces with most portable surface roughness gages via a USB connection. One click in TraceBoss configures the gage, initiates a measurement, and presents the results and graphics full screen and in high resolution. The software display is optimized for the highest visibility in shop environments.

With most portable gages, the profile and data cannot be easily saved or recalled. TraceBoss makes it possible for a gage user to save data and easily reload it for comparisons, traceability, and statistical process control.

TraceBoss calculates and reports most common roughness parameters. Optional tolerance highlighting shows at a glance whether a surface passes or fails relative to user-provided limits. A unique, side-by-side display clearly shows the relationship between Rk and Rq family parameters and the peaks and valleys that they describe.

A wide range of portable surface gages from Zeiss/ACCRETECH, Mahr, Taylor Hobson, and Jenoptik/HOMMEL ETAMIC connect to TraceBoss with minimal setup. The help system includes quick setup guides for each supported gage and step-by-step instructions for all software functions.

"TraceBoss is a fast, affordable way to better understand surface data," says Malburg. "It includes powerful features and the right parameters and settings for the most common measurement tasks. The bottom line is that TraceBoss makes surface roughness easy."