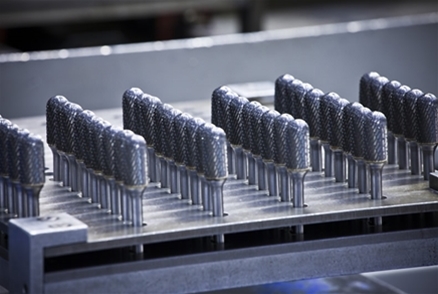

Tungsten-Carbide Burs in Multiple Configurations

Tungsten-Carbide Burs in Multiple Configurations

ATA designs, manufactures and distributes burs, with a selection exceeding 1,100 different types of high-quality tungsten-carbide burs. ATA offers bur configurations and specifications to suit every ferrous and nonferrous application, ensuring efficient stock removal and a fine surface finish.

ATA designs, manufactures and distributes burs, with a selection exceeding 1,100 different types of high-quality tungsten-carbide burs. ATA offers bur configurations and specifications to suit every ferrous and nonferrous application, ensuring efficient stock removal and a fine surface finish.

The AS (Alloy Specific) range has been designed to meet the most-demanding metal finishing needs on Ni-Alloys and Ti-Alloys in industries such as aerospace and power generation.

The Inox range offers high-performance grinding on stainless steel and inox materials, thanks to a unique cutting geometry.

The Steel range provides a more aggressive stock removal thanks to a unique cutting geometry, specifically designed to increase metal removal on steel components.