U5-3000 Universal Machining Center

U5-3000 Universal Machining Center

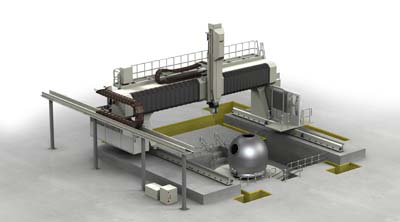

MAG's new U5-3000 Universal Machining Center combines massive platform capacity with long-reach 3-meter Z-axis and 5-axis, 5-side contour machining for efficient processing of large aluminum and composite parts.

MAG's new U5-3000 Universal Machining Center combines massive platform capacity with long-reach 3-meter Z-axis and 5-axis, 5-side contour machining for efficient processing of large aluminum and composite parts.

The newest addition to the U5 family of gantry mills, the U5-3000 is engineered to machine at extreme limits and into deep cavities of large prismatic parts. Combined with Y-axis travel of over 6 meters, unlimited X-axis travel, and high-speed, 15,000-rpm, 5-axis spindle, the U5-3000 brings machining efficiencies to extremely tall, wide and long parts. Its capacity provides versatility to large-part machining for aerospace, energy, marine, and die/mold applications.

The U5-3000's modular, heavy-duty gantry design delivers the stiffness, range and performance to machine complex part geometries with exceptional accuracy. A rigid box-way roller-bearing rail system and dual-motor rack-and-pinion X-axis drive provide smooth precise movement and high thrust levels on long-travel cuts. Feedrates up to 20 m/min (787 ipm) optimize processing efficiencies on large part surfaces.

Five-axis/five-side processing allows manufacturers to machine more part features in a single setup for lean efficiencies and higher productivity, while reducing potential errors caused by multiple setups on high-value parts. The U5-3000 comes standard with a 15,000-rpm, 30-kW (40.2 hp), HSK63A gimbal-style contouring spindle that delivers up to 57 Nm (42 lb-ft) torque for high-speed, high-throughput cutting performance.