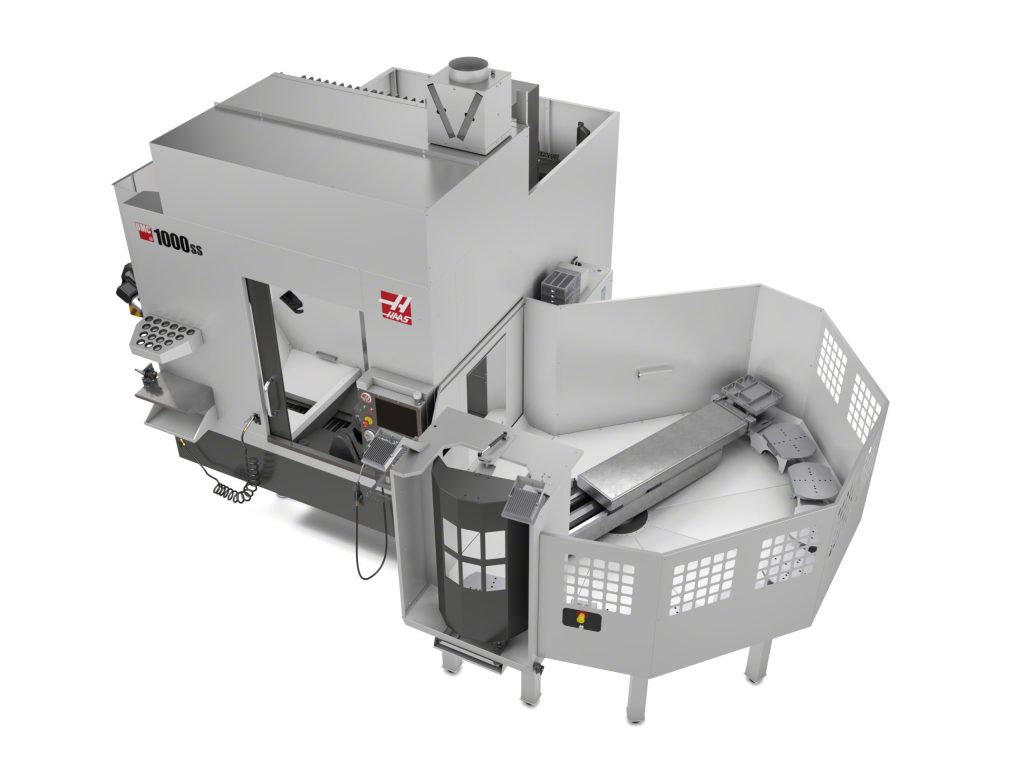

UMC-1000SS 5-Axis Universal Machining Center

UMC-1000SS 5-Axis Universal toolchanger. See automatic toolchanger." title="CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger." aria-label="Glossary: machining center">Machining Center

Haas Automation expands its line of affordable, 5-axis universal machining centers with the UMC-1000SS, a larger-travel, super-speed UMC that offers high performance and speed for 5-sided (3+2) machining and simultaneous 5-axis machining.

Haas Automation expands its line of affordable, 5-axis universal machining centers with the UMC-1000SS, a larger-travel, super-speed UMC that offers high performance and speed for 5-sided (3+2) machining and simultaneous 5-axis machining.

The UMC-1000SS is a 5-axis, 40-taper universal toolchanger. See automatic toolchanger." title="CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger." aria-label="Glossary: machining center">machining center with 40" x 25" x 25" (1016 x 635 x 635 mm) travels, 1200 ipm (30.5 m/min) rapids, and an integrated high-speed, dual-axis trunnion table. The machine is equipped with a 12,000-rpm inline direct-drive spindle, a high-speed 30+1 tool side-mount toolchanger and Haas Automation's high-speed machining software.

The UMC-1000SS's high-speed trunnion offers 170 deg/sec feed rates to quickly position parts for 5-side (3+2) machining, or provide simultaneous 5-axis motion for contouring and complex machining. The trunnion provides +120 and -35 degrees of tilt and 360 degrees of rotation for excellent tool clearance and large part capacity, and the 25" (635 mm) platter has standard T-slots and a precision pilot bore for fixturing versatility. To simplify job set up, the UMC-1000SS features Dynamic Work Offsets and Tool Center Point Control, and comes standard with Haas Automation's Wireless Intuitive Probing System.

The machine's 12,000-rpm inline direct-drive spindle is powered by a 30-hp (22.4 kW) vector drive system that yields 90 ft-lb (122 Nm) of cutting torque. A 15,000-rpm spindle is also available, in either standard 40-taper or dual-contact HSK-A 63 taper.

For high-volume production, high-mix/low-volume machining and unattended operation, the UMC-1000SS is available with an optional 8-station pallet pool. A wide selection of high-productivity options is also available, including a 50+1 tool side-mount toolchanger, a belt-type chip conveyor and through-spindle coolant.