VGM-NIK & the VGM3-AL

VGM-NIK & the VGM3-AL

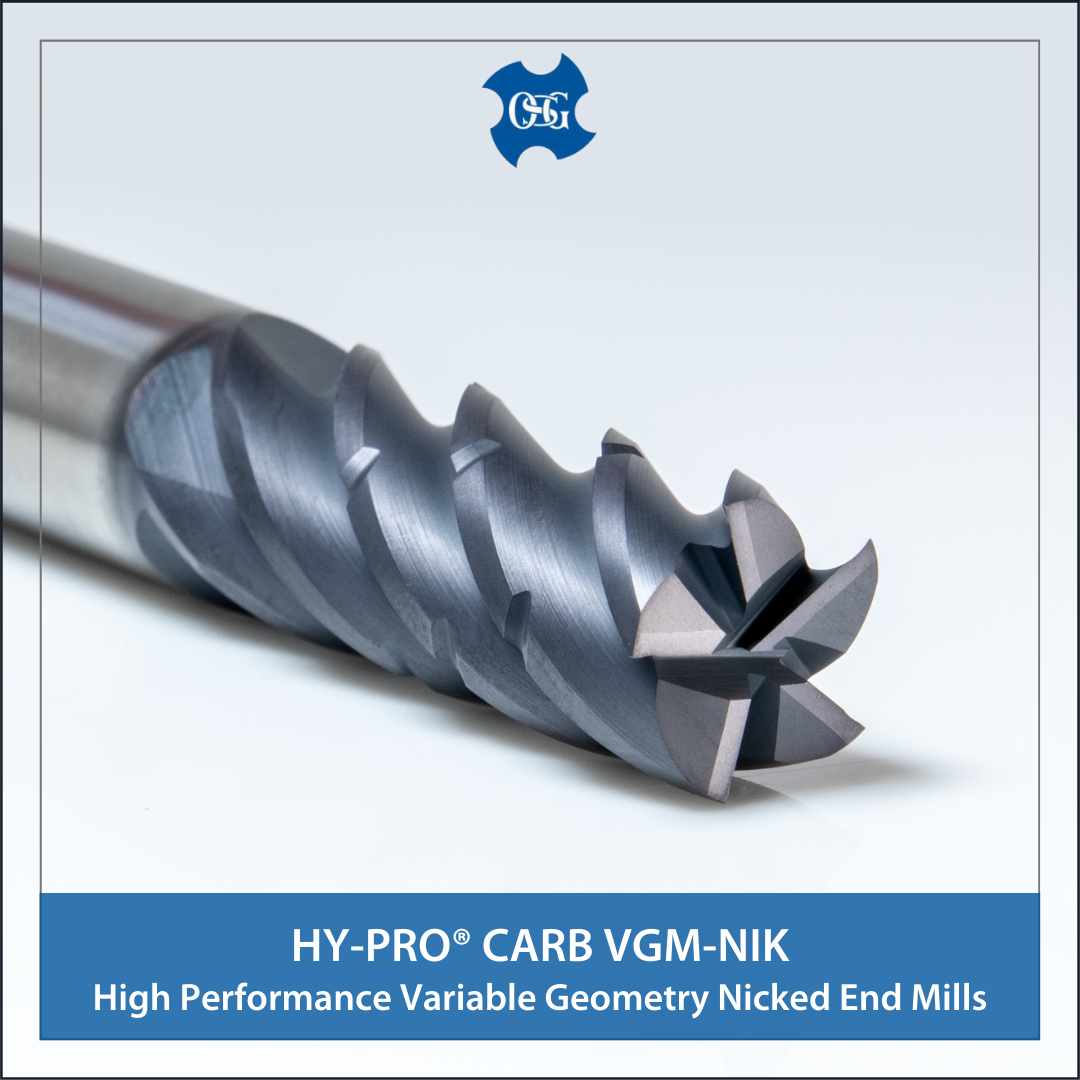

The HY-PRO® CARB VGM-NIK offers the following features & benefits: Variable Index - Reduces vibration during machining. Unique Flute Geometry - Maintains excellent cutting-edge sharpness and tool rigidity. EXO Coating – Provides longer tool life through exceptional wear and heat resistance. Chipbreaker – Creates small manageable chips.

OSG USA, INC. is pleased to announce the expansion of our HY-PRO® CARB VGM offering with the addition of the NEW VGM-NIK & the NEW VGM3-AL high-performance variable geometry end mills.

VGM-NIK

We are pleased to announce the expansion of our HY-PRO® CARB VGM offering with the addition of the NEW VGM-NIK high-performance variable geometry nicked end mills.

The following list numbers are associated with the HY-PRO® CARB VGM Series Expansion:

- List #VGM5-NIK HY-PRO® CARB VGM5-NIK

- List #VGM7-NIK HY-PRO® CARB VGM7-NIK

The HY-PRO® CARB VGM-NIK offers the following features & benefits:

- Variable Index - Reduces vibration during machining

- Unique Flute Geometry - Maintains excellent cutting-edge sharpness and tool rigidity

- EXO Coating – Provides longer tool life through exceptional wear and heat resistance.

- Chipbreaker – Creates small manageable chips

VGM3-AL

We are pleased to announce the expansion of our HY-PRO® CARB VGM offering with the addition of the NEW VGM3-AL high-performance variable geometry end mill for aluminum.

The following list numbers are associated with the HY-PRO® CARB VGM Series Expansion:

- List #VGM3-AL HY-PRO® CARB VGM3-AL

The HY-PRO® CARB VGM3-AL offers the following features & benefits:

- Variable Index - Reduces vibration during machining

- Unique Flute Geometry - Maintains excellent cutting-edge sharpness and tool rigidity

- Center Cutting – 3 cutting edges to center; ideal for plunging and ramping