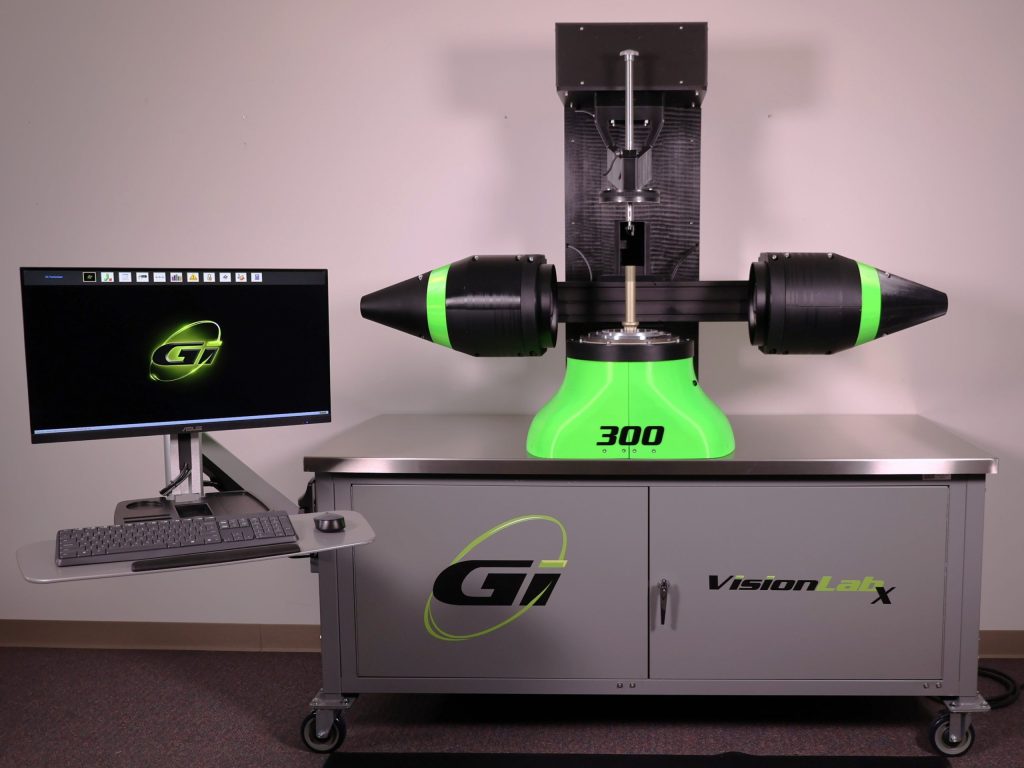

VisionLab-X-300

VisionLab-X-300

Equipped with high-resolution cameras and custom lenses, the VisionLab-X-300 handles parts up to 12 inches (300mm) in length and 2 inches (50mm) in diameter, offering precise measurements for complex features (achieving part measurements within two microns). Enhanced slewing optics allow for accurate pitch diameter and root radii measurements, while the bottom vision system—featuring a rotating sapphire stage and LED front lighting—supports thorough inspections of internal and external diameters, concentricity, roundness, thickness, and head stamp details.

A prominent steel manufacturer with a large bolt producing division in the Midwest recently installed a new VisionLab-X-300, 3D Fastener Gauging System from General Inspection, LLC. As part of their commitment to advancing quality control processes, they implemented this state-of-the-art system to streamline production and ensure the highest standards of quality and reliability.

The VisionLab-X-300 utilizes General Inspection's patented 3D gauging technology to deliver comprehensive part dimensional layouts in less than 7 seconds. Capable of performing 360°-dimensional inspection with detailed data reporting, the system includes a bottom vision system for verifying head stamps and measuring recess features. This installation provides significant time savings and accuracy by eliminating old school human subjective measuring techniques.

Equipped with high-resolution cameras and custom lenses, the VisionLab-X-300 handles parts up to 12 inches (300mm) in length and 2 inches (50mm) in diameter, offering precise measurements for complex features (achieving part measurements within two microns). Enhanced slewing optics allow for accurate pitch diameter and root radii measurements, while the bottom vision system—featuring a rotating sapphire stage and LED front lighting—supports thorough inspections of internal and external diameters, concentricity, roundness, thickness, and head stamp details.

An optional top confinement and recess tooling bit kit adds versatility, with staging and adjustable upper tooling to accommodate various part geometries. The system's intuitive software provides custom data reports that can be exported as CSV or Excel files. This manufacturer also leverages the built-in MySQL server for direct integration with their SPC program.

The VisionLab-X-300 is a versatile, accurate, and fast inspection machine capable of handling a wide range of applications.