VITRA Vitrified-Bond Grinding Wheels

VITRA Vitrified-Bond Grinding Wheels

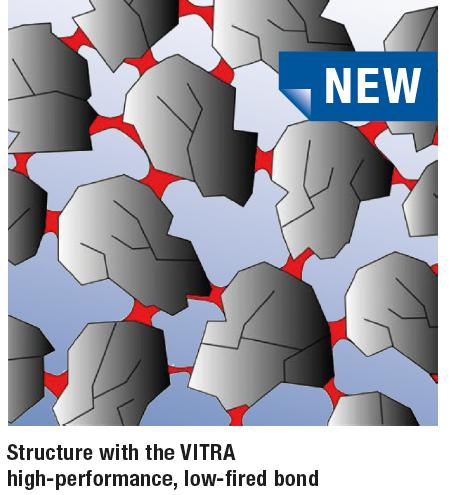

VITRA represents the latest generation of vitrified-bonded Hermes precision grinding tools. This newest achievement of the Hermes research laboratories is based on an advanced high-performance, low-fired bond and an optimized microstructure.

VITRA represents the latest generation of vitrified-bonded Hermes precision grinding tools. This newest achievement of the Hermes research laboratories is based on an advanced high-performance, low-fired bond and an optimized microstructure.

VITRA grinding wheels are available in in all aluminum-oxide abrasive types, including sintered aluminium-oxide grain and grit sizes up to 200.

Benefits:

- Optimized pore structure to increase the intake of coolant and improved chip removal.

- Significantly low temperature stress during grinding and, thus, shorter grinding times with higher material-removal rates.

- Universal use with fused and sintered aluminum oxide.