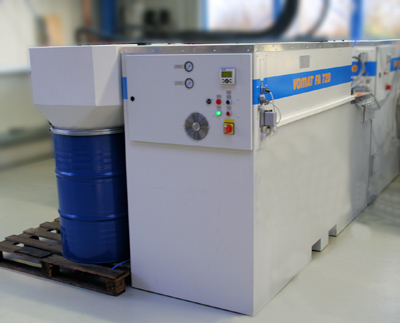

Vomat FA Coolant Filtration Equipment

Vomat FA Coolant Filtration Equipment

In tool grinding all individual processing steps are part of a coherent value chain. Therefore, it is important that the filtration process of metal coolants is integrated seamlessly in this value chain. When operational requirements or technical improvements cause changes and flexibility is needed, the filtration system should meet those new needs. The filtration specialist Vomat meets these challenges with a line-up of high-tech systems.

In tool grinding all individual processing steps are part of a coherent value chain. Therefore, it is important that the filtration process of metal coolants is integrated seamlessly in this value chain. When operational requirements or technical improvements cause changes and flexibility is needed, the filtration system should meet those new needs. The filtration specialist Vomat meets these challenges with a line-up of high-tech systems. From stand alone to large industrial central filtration systems Vomat's offerings are of modular design and can be adapted quickly and easily to changing shop and production requirements.

Stephan Hecht of oelheld U.S. Inc., Vomat's general agent in Elgin, Ill., states: "By design the stand alone Vomat-FA-series models have a flow capacity of 120 to 960 liters per minute. In addition, we provide our customers with a number of add-on modules which can be easily integrated, when the need arises. The array of modules includes displays for the complete visualization of the filtration process in real time, frequency controlled pumps, internal and external pre-filters and various cooling solutions. In close cooperation with the customer, Vomat tailors a filtration solution to individual production conditions, which can be can be altered in case requirements change. If our client implements technological improvements in his production process, Vomat can help to make sure that the filtration system will meet the new requirements."

Besides the modular expandability of Vomat systems, it is mainly the innovative filter technology that provides Vomat customers with economic benefits: Vomat systems filter in full flow stream and separate dirty from clean oil 100 percent, thanks to high capacity pre-coated filters. The results are lubricants, which meet NAS 7/8 or 3-5µm in terms of purity and cleanliness. Clean oil is decisive for dimensional accuracy and surface quality of the finished work piece.

In addition, Vomat systems adapt intelligently to changing volumes of sludge and automatically initiate the backflush cycle depending filter contamination. Each Vomat machine is equipped with enough filters, that during the backflush cycle the operator always has full oil flow. This allows for energy efficient, time optimized operation in sync with the customer's grinding machine. The Vomat FA 120 through 420 series machines with dimensions of 1 x 1 x 1,6 meters are also significantly smaller than comparable filtration systems on the market. This keeps transportation costs low, possibly reduces facility alterations and provides the client with more floor space.

Flexibility and customer satisfaction are paramount at Vomat. Hecht said: "We analyze the requirements of each operation exactly in order to supply the optimal system. Many times customers invite us early on to be involved in the planning phase when new operations or modifications to existing ones are planned. Even operations where frequent changes are common are always in good shape with Vomat filtration."