VpCI-126 Vacuum Bags

VpCI-126 Vacuum Bags

These bags take the protection of basic VpCI®-126 Film to the next level by adding an extra barrier against moisture and oxygen for enhanced corrosion inhibition during long-term storage or harsh shipping conditions. The bags can be vacuum-packed and are ideal for automotive build-ahead programs, all-time-buys, or other long-term metal storage applications.

Cortec® Corporation is pleased to announce the release of a new high performance VpCI® packaging product: VpCI®-126 Vacuum Bags! These bags take the protection of basic VpCI®-126 Film to the next level by adding an extra barrier against moisture and oxygen for enhanced corrosion inhibition during long-term storage or harsh shipping conditions. The bags can be vacuum-packed and are ideal for automotive build-ahead programs, all-time-buys, or other long-term metal storage applications.

Metals packaged inside VpCI®-126 Vacuum Bags receive continuous protection against salt, excessive humidity, condensation, moisture, aggressive industrial atmospheres, and dissimilar metal corrosion. The

VpCI® molecules in the film vaporize and condense on metal surfaces in the enclosed package, forming a protective molecular film that does not need to be cleaned off before the contents can be used. The following metals are protected:

-

Aluminum

-

Galvanized Steel

-

Carbon Steel

-

Stainless Steel

-

Copper

-

Brass

- Cast Iron

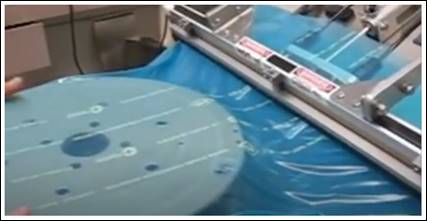

VpCI®-126 Vacuum Bags are a great way to unitize loads and eliminate rubbing of small parts during transit and storage. Packaging is as simple as placing the clean dry parts inside the bags and sealing them with standard vacuum-packaging equipment. The see-through film makes it easy to identify parts packed inside the bags without having to open the package and break the vacuum-packed seal. All the while, the metal parts inside continue to be protected against moisture, oxygen, and corrosion without requiring conventional rust preventatives such as oils and desiccants.

Many practical uses await VpCI®-126 Vacuum Bags. For example, when automakers retire a vehicle model, they make extra service parts ahead of time to avoid expensive small volume runs in the future. A good storage plan is critical to keeping parts in like-new condition for whenever they may be needed. VpCI®-126 Vacuum Bags are an excellent packaging option that seals and protects the metal parts against corrosion and moisture in a transparent blue bag that allows for easy component identification.

The same is true for a variety of industries that need to preserve spare parts or lay up small equipment—from those on offshore platforms to inside paper mills. Almost every industrial site has small metal parts

that need to be packed away for long-term safe-keeping until later use. Rather than coat small nuts and bolts and other assorted components in a greasy rust preventative and throw them in a traditional plastic bag with a desiccant pouch, workers can neatly pack away small metal items in VpCI®-126 Vacuum Bags for long-term protection.

The possibilities are endless for this convenient and exciting new form of vacuum-packaging and corrosion protection known as VpCI®-126 Vacuum Bags. Contact Cortec® today to learn more: https://www.cortecvci.com/contact-us/!

Relevant test methods for VpCI®-126 Vacuum Bags include NACE TM0208-2008, German TL-8135-002, and MIL-PRF-22019E(1) (commercial equivalence).