VSM490 Double-Sided Shoulder Mills

VSM490 Double-Sided Shoulder Mills

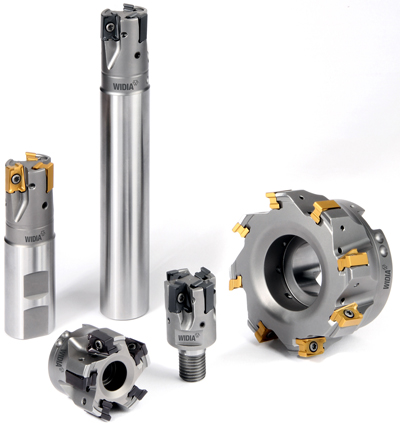

The new VSM490 double-sided shoulder milling platform from WIDIA offers an advantage for achieving true 90-degree shoulders and floors with superior surface finish.

The new VSM490 double-sided shoulder milling platform from WIDIA offers an advantage for achieving true 90-degree shoulders and floors with superior surface finish. Numerous precision parts in transportation, moldmaking, general engineering, and more require true 90-degree shoulders and floors with superior surface finish. Economic and competitive pressures require manufacturers of all parts to maximize metal removal and tool life. The new VSM490 double-sided shoulder milling platform from WIDIA is a powerful advantage for achieving all this and more.

"Go ahead and get aggressive with feed rates," says Global Product Manager Juan Seculi. "Not only will you see the depth of cut is much bigger (up to 15mm or 0.590 inches), scallop or stepdown marks are barely noticeable. Poor surface quality means additional operations and higher cycle times. Take the VSM490 performance upgrade and add that double-sided inserts deliver a sizeable cost benefit over single-sided tools and the VSM490 advantages become compelling."

Designed for low horsepower draw and free machining, VSM490 delivers an effective one-two punch of reduced horsepower at the machine and higher speed and feed rates that get jobs done faster and/or with an improved surface quality.

With four cutting edges and multiple corner nose radii available, the robust VSM490-15 inserts provide added stability and reliability in addition to delivering true 90-degree shoulders and floors. Two insert geometries are available:mm (universal), making it the first choice for a range of work materials; and ML (light) with sharper cutting edges resulting in lower cutting forces for mild steels and stainless.

VSM490 cutter bodies made with tight tolerances to ensure minimum run-out have an integral chip gash design for excellent chip evacuation along with hardened-steel construction and hardened pocket seats for improved resistance to deformation. They are available in shell, screw on, cylindrical shank, and Weldon shank models with internal air and coolant capability.

"The VSM490 portfolio is engineered for multiple applications in multiple materials, making it a go-to milling tool," Seculi says. "Users should expect true 90-degree shoulders and floors, superior surface finish on both, and higher metal-removal rates at lower horsepower for savings all around."

Moreover, VSM490 is available through NOVO, WIDIA's digital process knowledge application. With powerful process knowledge available on iPad and other digital devices, NOVO helps users define machining features, such as shoulder milling in specific work materials, and then immediately reduces the product set to those like VSM490 that can do the job, taking into account constraint requirements such as material, tolerance, and machining sequence for both single tools and multi-tools. NOVO then ranks the results—based on knowledge-based rules—to best meet the challenges of the application as defined by the customer's operating environment and user preferences. This provides far more useful process knowledge than any online catalog alone, all obtained in a fraction of the time.