Contact Details

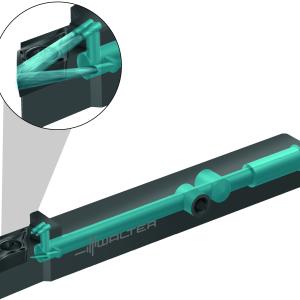

Walter USA LLC hasenhanced its versatile family of Xtra-tec Insert Drills with the addition of the Walter Capto clamping system and indexable inserts with Tiger-tec Silver cutting tool material. The Xtra-tec Insert Drills range in diameter from 16 to 45mm, with a depth of cut of 3xD, and feature optimized chip clearance for reliable chip evacuation. They can be used on a variety of materials ranging from steel and cast iron to stainless and difficult-to-cut materials, and can handle chain drilling, sloping, and convex surfaces.

Now, the addition of the Walter Capto clamping system provides higher transmission of force via the system's polygonal interface, high process reliability due to the positive locking of the indexable inserts with TorxPlus screws, and faster tool changing. In addition, its hard-nickel plated surface provides protection against corrosion and wear, and its cylindrical collar promotes straightforward measurement of the tool diameter.

The high-performance Tiger-tec Silver cutting tool material also helps improve the performance of the new drill. The indexable inserts, available in three different geometries and four different grades, have four cutting edges, enabling high cutting parameters and helping to reduce the number of additional operations necessary. The ground indexable inserts are also fitted with a wiper edge, ensuring superior finish.

Related Glossary Terms

- chip clearance

chip clearance

In milling, the groove or space provided in the cutter body that allows chips to be formed by the inserts.

- clearance

clearance

Space provided behind a tool’s land or relief to prevent rubbing and subsequent premature deterioration of the tool. See land; relief.

- depth of cut

depth of cut

Distance between the bottom of the cut and the uncut surface of the workpiece, measured in a direction at right angles to the machined surface of the workpiece.

- wiper

wiper

Metal-removing edge on the face of a cutter that travels in a plane perpendicular to the axis. It is the edge that sweeps the machined surface. The flat should be as wide as the feed per revolution of the cutter. This allows any given insert to wipe the entire workpiece surface and impart a fine surface finish at a high feed rate.

PRODUCTS

PRODUCTS