Contact Details

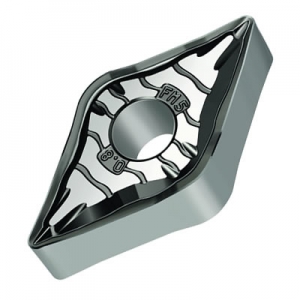

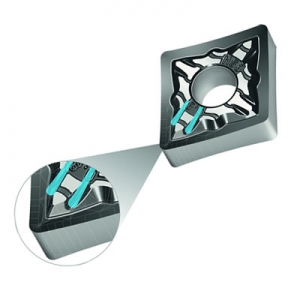

Walter USA LLC has unveiled the new Walter Titex reamers. These new reamers are solid carbide up to 13mm diameter; above that sized diameter they have a solid carbide head. The reamers feature shank tolerance of h6 according to DIN 6535 HA and come in two versions: The straight fluted F2162 for blind and through holes, which comes in sizes ranging from 4 to 20mm in diameter, while the spiral fluted F2171 for through holes is available in sizes ranging from 2 up to 20mm diameter. Both versions have diameter tolerance for h7 hole size, and cutting geometry that features unequal division for best roundness and surface quality.

The versatile new reamers are engineered for use on steel (ISO P), stainless steel (M), cast iron (K), aluminum (N), heat resistant alloys (S), and hardened steels (H), as well as composites and plastics (O) rendering them well suited for the automotive, aircraft, energy and medical device industries, as well as general metalworking. They can help boost productivity, thanks in part to the fact that they are usable on machining centers with shrink fit and hydraulic chucks, and deliver reliable tool life due to their high run-out accuracy, thus enhancing process reliability. They also deliver optimal surface quality and roundness.

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- composites

composites

Materials composed of different elements, with one element normally embedded in another, held together by a compatible binder.

- metalworking

metalworking

Any manufacturing process in which metal is processed or machined such that the workpiece is given a new shape. Broadly defined, the term includes processes such as design and layout, heat-treating, material handling and inspection.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

- tolerance

tolerance

Minimum and maximum amount a workpiece dimension is allowed to vary from a set standard and still be acceptable.

PRODUCTS

PRODUCTS