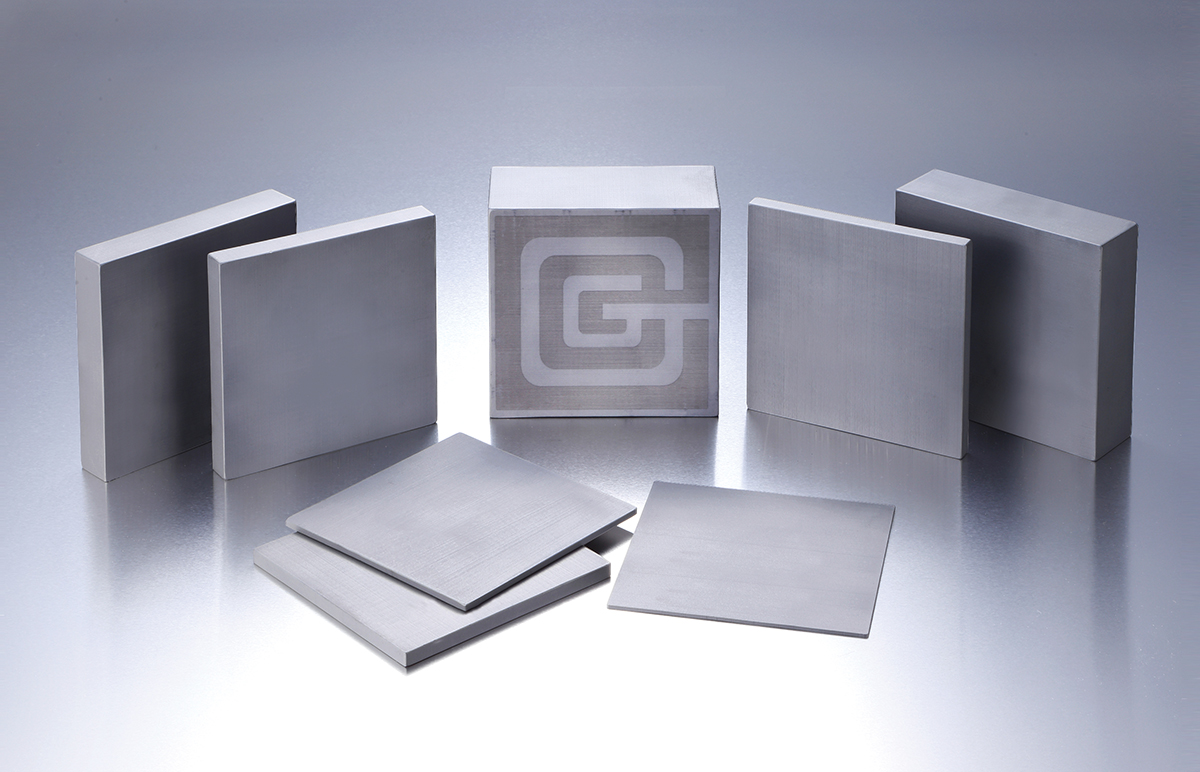

Wire EDM Blocks

Wire EDM Blocks

General Carbide has expanded its operations to produce more than 40 standard and custom sizes of wire EDM blocks for a range of stamping and fabricating applications. To help ensure that blocks are of the highest metallurgical quality and reach customers intact and quickly, the company processes every order in sinter-HIP furnaces, ships the blocks in durable packaging, guarantees turnaround of 3 to 5 business days and tracks shipments door-to-door.

General Carbide has expanded its operations to produce more than 40 standard and custom sizes of WEDM blocks for a range of stamping and fabricating applications. To help ensure that blocks are of the highest metallurgical quality and reach customers intact and quickly, the company processes every order in sinter-HIP furnaces, ships the blocks in durable packaging, guarantees turnaround of 3 to 5 business days and tracks shipments door-to-door.

"Providing superior grades and more WEDM options is the result of listening to customers and prospects, making a significant capital investment," said Mona Pappafava-Ray, General Carbide's president and CEO. "Our submicron grain size of tungsten carbide particles is ideal for wear resistant grades capable of withstanding moderate impact loads. In contrast, our 4-micron carbide particle grain size and use of tantalum carbide yield a WEDM block that offers the highest resistance to galling."