Contact Details

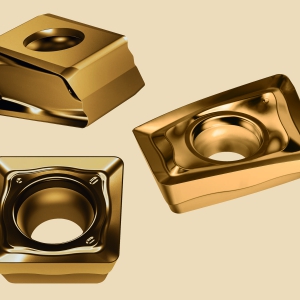

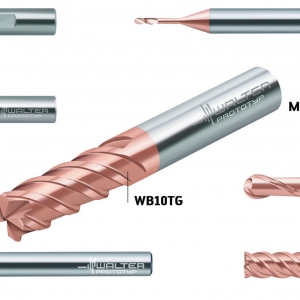

Walter has introduced the WL17 indexable insert in neutral, right-hand and left-hand versions for copy turning (profiling). The tools that accept the WL17 indexable insert include the Walter Turn W1011-S-P external turning toolholders for Swiss-type automatic lathes and multiple-spindle machines, and the W1210/W1211 boring bars for internal profiling, facing and axial grooving. Neutral, right-hand and left-hand inserts can be used in the same tool.

The W1011-S-P toolholder enables forward and reverse turning (towards and away from the spindle). It uses cutting edges from both the sides of the 35° included angle of the insert corner and runs at high feed rates. The inserts maximize tool life because of the option of performing forward or reserve turning as well as the unique insert pocket and support.

The inserts feature three cutting edges at a 50° copying angle. Compared to the WL25 indexable inserts, which measure 25 mm per side, the WL17 inserts measure 17 mm per side. The WL25 inserts are now additionally offered in W0110-C Walter Capto tools and the W1211 QuadFit exchangeable head for Accure.tec anti-vibration boring bars.

The inserts provide a high level of stability against the tendency for vibrations in cut due to the robust Walter Turn WL positive engagement system. This WL positive engagement system makes use of innovative seating surface sintered into the base of the carbide insert that engages against a 3-pocket insert seat of the tool. The inserts enable 50% higher indexing accuracy compared to conventional ISO indexable inserts.

Rake face cooling is optimized on the toolholder for effective chip removal, particularly on Swiss-style automatic lathes and multiple-spindle machines.

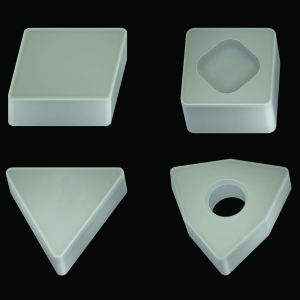

The WL17 indexable inserts are suitable for copy turning of radial undercuts up to 30° or 50° and axial undercuts of 30° and profiling high-precision components. The three-sided WL inserts are ideal replacements for ISO VBMT, VCMT, DCMT indexable inserts, which have just two cutting edges and a lower level of stability.

Related Glossary Terms

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- grooving

grooving

Machining grooves and shallow channels. Example: grooving ball-bearing raceways. Typically performed by tools that are capable of light cuts at high feed rates. Imparts high-quality finish.

- included angle

included angle

Measurement of the total angle within the interior of a workpiece or the angle between any two intersecting lines or surfaces.

- indexable insert

indexable insert

Replaceable tool that clamps into a tool body, drill, mill or other cutter body designed to accommodate inserts. Most inserts are made of cemented carbide. Often they are coated with a hard material. Other insert materials are ceramic, cermet, polycrystalline cubic boron nitride and polycrystalline diamond. The insert is used until dull, then indexed, or turned, to expose a fresh cutting edge. When the entire insert is dull, it is usually discarded. Some inserts can be resharpened.

- profiling

profiling

Machining vertical edges of workpieces having irregular contours; normally performed with an endmill in a vertical spindle on a milling machine or with a profiler, following a pattern. See mill, milling machine.

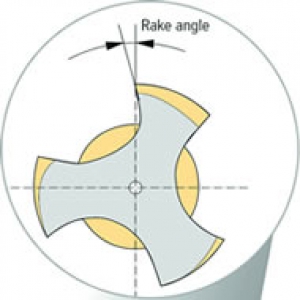

- rake

rake

Angle of inclination between the face of the cutting tool and the workpiece. If the face of the tool lies in a plane through the axis of the workpiece, the tool is said to have a neutral, or zero, rake. If the inclination of the tool face makes the cutting edge more acute than when the rake angle is zero, the rake is positive. If the inclination of the tool face makes the cutting edge less acute or more blunt than when the rake angle is zero, the rake is negative.

- toolholder

toolholder

Secures a cutting tool during a machining operation. Basic types include block, cartridge, chuck, collet, fixed, modular, quick-change and rotating.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

PRODUCTS

PRODUCTS