ZeroAct E-motion

ZeroAct E-motion

Ideal for Industry 4.0, ZeroAct e-motion features wireless connectivity and data transfer, and fully automates manufacturing processes using a 24V power supply that operates with a built-in electro-motor. In addition, integrated electronic sensor technology provides contact-free part detection and safety for missing or misaligned parts.

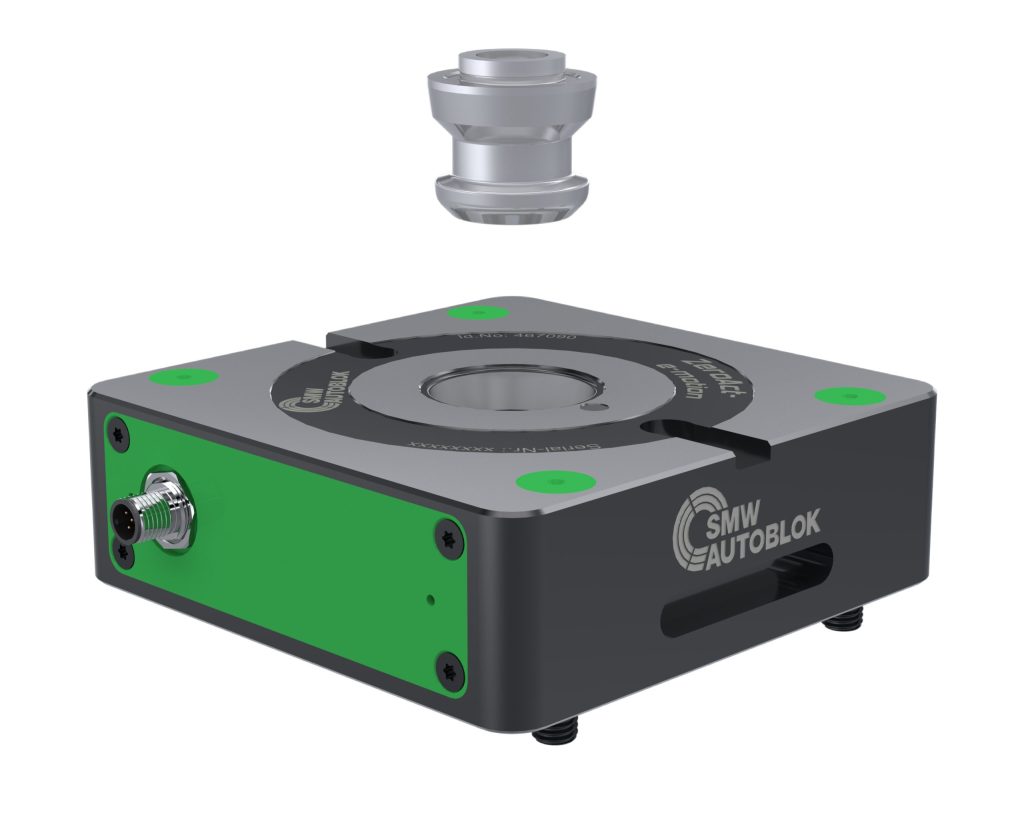

SMW Autoblok, a world leader in the design and manufacture of rotational chucks, stationary workholding, tooling and engineered solutions for the machine tool industry, introduces the electronic ZeroAct E-motion automatic positioning system featuring Zero Point clamping used in a variety of machining applications including milling, inspection, finishing, clean room operations and 3D printing.

Ideal for Industry 4.0, ZeroAct e-motion features wireless connectivity and data transfer, and fully automates manufacturing processes using a 24V power supply that operates with a built-in electro-motor. In addition, integrated electronic sensor technologyprovides contact-free part detection and safety for missing or misaligned parts.

With an ultralow profile of 48 mm and extremely flat design, ZeroAct E-motion is ideal for any Zero Point application especially those where a large Z-axis travel of the spindle is critical for success.

The modular ZeroAct E-motion system, with a compact size of 150 x 150 mm, provides a repeat accuracy of < 5 µm and holding force of 35, 50, or 75 kN depending on thread of clamping pin.

The electronic ZeroAct E-motion is part of the comprehensive lineup of plug & play mechatronic workholding products including chucks and stationary workholding for intelligent part holding.