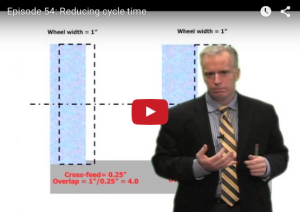

Reducing cycle time

A shop surface grinding 12" x 36" plates has to remove 1/8" of material on both sides, but the cycle time is a killer. To find a way to reduce the cycle time, the shop turned to Dr. Jeffrey Badger, author of the "Ask the Grinding Doc" column in Cutting Tool Engineering magazine and the host of our Grinding Doc Video Series.