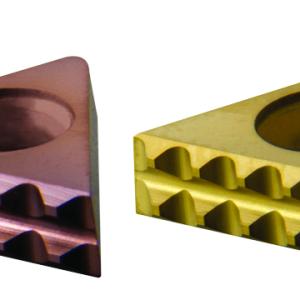

Unique to Nikken rotary tables is the innovative and patented carbide worm system comprised of a carbide worm screw, ion nitrided worm wheel (HV930), and hardened steel bearing surface (HRC58-60). The V grade solid carbide worm screw helps to ensure high rigidity and virtually eliminates wear. Compared with traditional worm system combinations (consisting of phosphorus bronze and aluminum bronze), wear is reduced by up to 8 times, and overall accuracy is substantially increased. Additionally, the worm wheel has specially hardened, ion-nitrided treated teeth that eliminate sliding friction.