Software/CNC

Westec 2023 Booth Visit with CGTech and Scytec

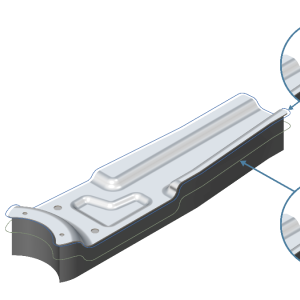

Scytec Consulting Inc. President and CEO Josh Davids and CGTech Director of Product Management Gene Granata discussed the ability of CGTech’s Vericut software to produce CNC simulation, verification, optimization and connecting to CNC machines.