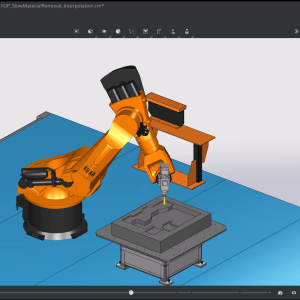

Software/Computer Aided Manufacturing

IMTS 2022 Booth Visit with OPEN MIND Technologies

Alan Levine, managing director for OPEN MIND Technologies USA Inc., highlights the advancements of the company's hyperMILL® CAM software with an overview of several sample components manufactured with the software.

Click here to visit the OPEN MIND Technologies website.

Optimize machining to protect your tools

As this video testimonial shows, Sandvik Coromant, Mebane, North Carolina, trusts CGTech’s VERICUT Force to optimize their toolpaths for better results through complicated cuts while preventing tool deflection, spikes in load, and breakage. Force optimization reduces unnecessary wear and tear on cutters, improves the quality of finished components, and decreases cycle times.