Software/Metalcutting

IMTS 2022 Booth Visit with CGTech

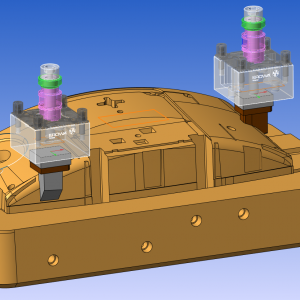

Along with a discussion of how VERICUT software helps intelligent cutting tools with optimization, CGTech debuted its CNC Machine Connect system, which features Precheck and Live Monitoring modules.

Click here to visit CGTech's website.