Heckert DBF 630 6-axis Machining Center

Heckert DBF 630 6-axis Machining Center

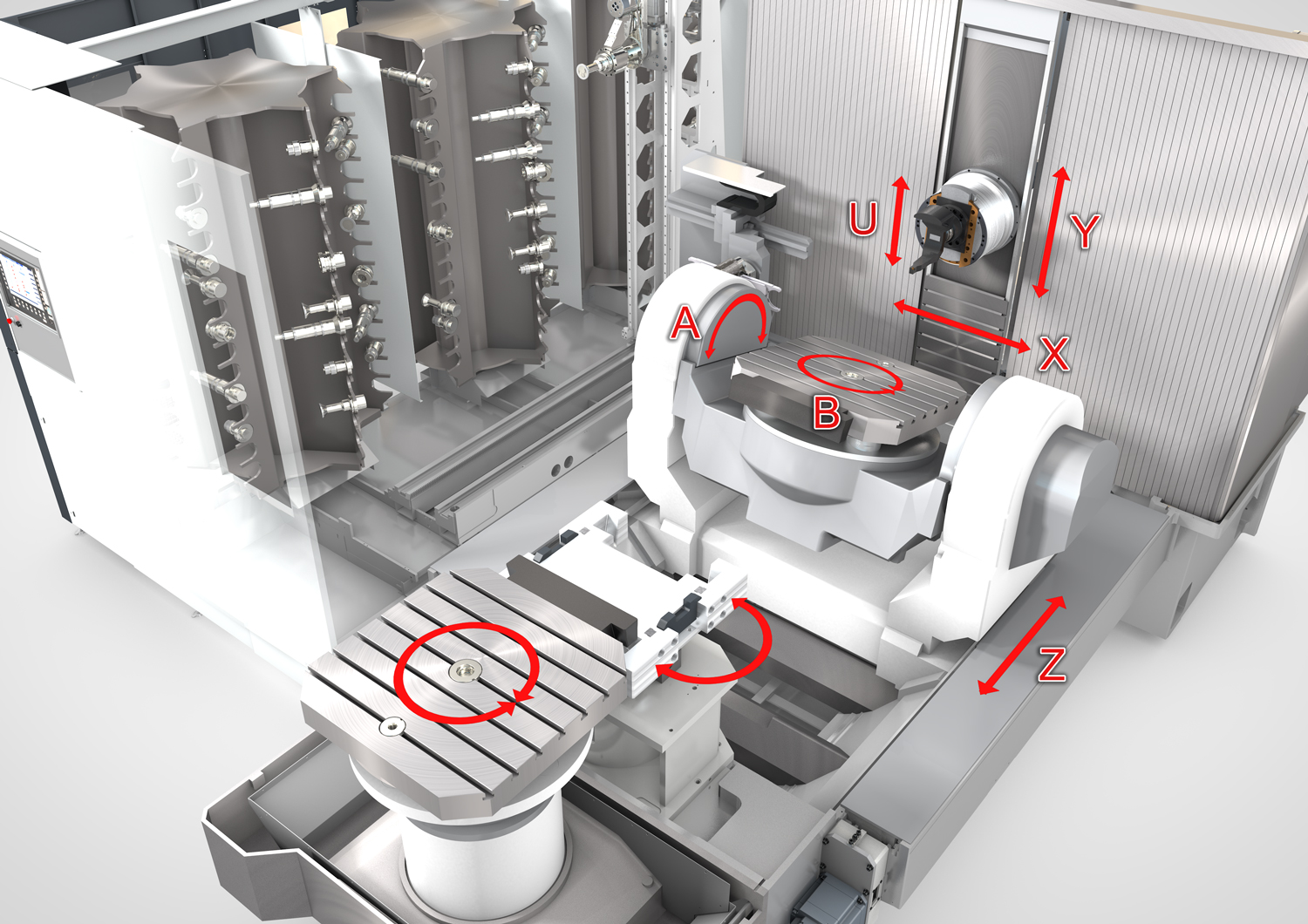

Starrag offers the innovative Heckert DBF 630 6-axis machining center with B over A trunnion table coupled with 45 kW (60 hp)/1,700 Nm (1,254 ft-lb) torque fully integrated U axes head to enable turning, as well as milling, boring, drilling and thread generation operations to be completed in a single setup. OEMs and top-tier suppliers in the oil and gas market, for example, are making significant savings on workpieces such as fluids ends, gate valves, drill bits and pump housings.

Starrag offers the innovative Heckert DBF 630 6-axis machining center with B over A trunnion table coupled with 45 kW (60 hp)/1,700 Nm (1,254 ft-lb) torque fully integrated U axes head to enable turning, as well as milling, boring, drilling and thread generation operations to be completed in a single setup. OEMs and top-tier suppliers in the oil and gas market, for example, are making significant savings on workpieces such as fluids ends, gate valves, drill bits and pump housings. A perfect example for Starrag´s claim "Engineering precisely what you value."

The Heckert DBF 630 machining center has 630 mm by 630 mm pallets that can accommodate loads of 1,000 kgs and there is a 40-tool ATC as standard.

The DBF head permits in a single set-up milling, boring, drilling and turning - comprising a faceplate with integrated work spindle and CNC radial facing slide.

For turning on a fixed workpiece, the rotating turning tool, which has an axial runout of just 5 to 6 microns, can be radially adjusted by +/-35 mm. In addition to external, internal and face turning, the head also permits conical and contour turning courtesy of the radial facing slide's NC axis.

For milling and drilling, the work spindle is arranged in its central position.