New carbide grade for milling cast iron

New carbide grade for milling cast iron

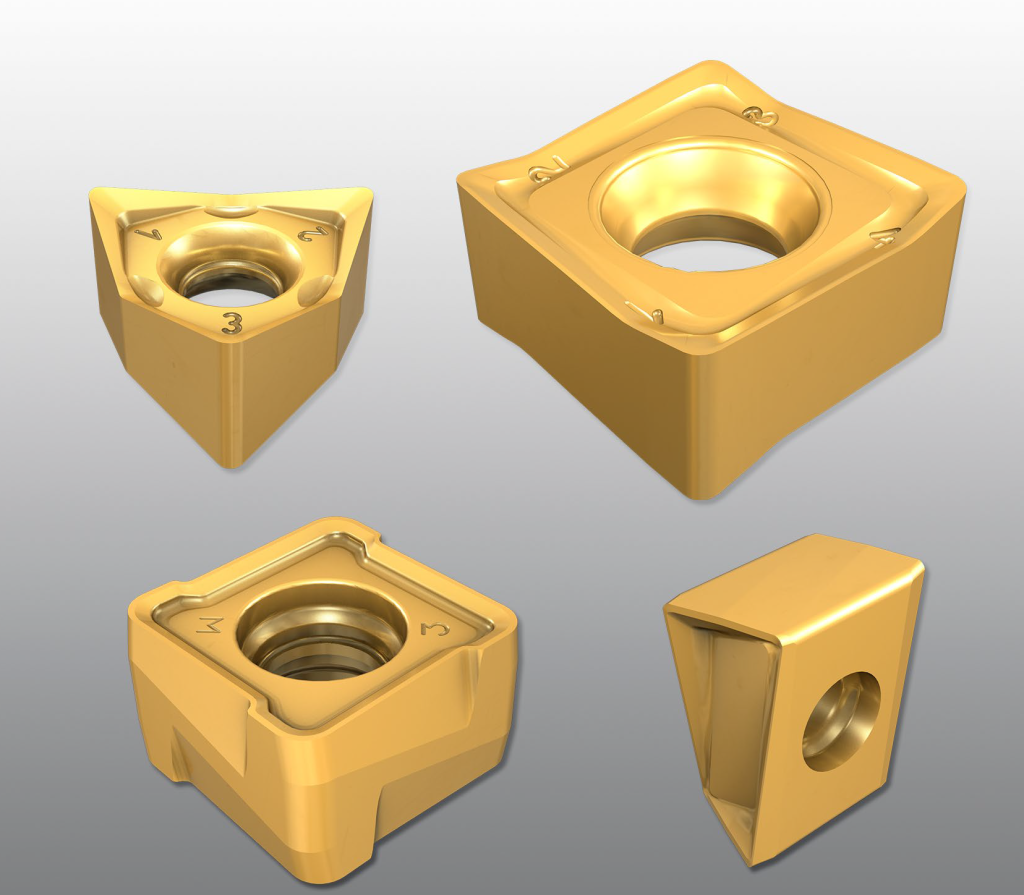

ISCAR is introducing a new PVD-coated carbide grade that is intended for indexable milling cast iron (ISO K group of application).

ISCAR is introducing a new PVD-coated carbide grade that is intended for indexable milling cast iron (ISO K group of application).

The grade, designated as IC1011, is designed for machining cast iron (ISCAR material groups 15-20), primarily nodular cast iron (ISCAR material groups 17-18), in demanding conditions such as heavy-duty applications, unstable cutting, and other challenging scenarios.

Also, IC1011 is suitable for operations performed with wet coolant supply. The new grade is characterized by a tough cemented carbide substrate and a new PVD AlTiN coating with outer yellow color for easy wear detection.

IC1011 features an ISO application range of (K15-K40). It has been tested across various milling applications for cast iron grades representing the main types of cast iron. The obtained results demonstrate that this new grade provides customers with an effective complementary carbide solution for successful milling of cast iron, particularly nodular cast iron, even in severe environments.

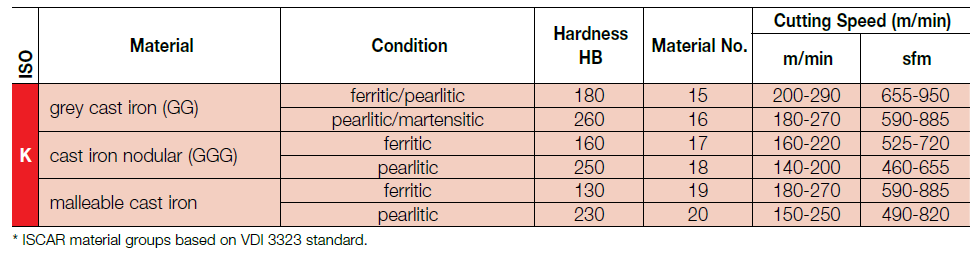

Cutting data

The recommended operating range of cutting speeds is shown in table below. Regarding feed rates, IC1011 generally allows for higher feed per tooth when compared to ISCAR’s existing carbide grades for indexable milling of cast iron. For more detailed feed recommendations and other cutting data, please refer to our information sources (e-catalog, printed catalog, leaflets, etc.) related to specific products.