Exit Nozzle: A Good Idea?

Exit Nozzle: A Good Idea?

Shop asks the Grinding Doc to address whether mounting a nozzle at the wheel/workpiece exit point can improve coolant effectiveness in grinding operations.

Dear Doc: Some machine operators like to mount a nozzle at the wheel/workpiece exit point. Some don't. What's your take? Does it help cool the workpiece?

The Doc replies: For the vast majority of grinding operations, putting a coolant nozzle at the exit (assuming you are doing up-grinding and not down-grinding) won't help you remove heat from the hot-spot in the grinding zone.

The exception might be (and this is a big "might") creep-feed grinding. Why? Because at the exit there is no workpiece heat-sink to conduct away heat. Therefore, some coolant at the exit will convect away some heat and reduce bulk temperature, and, in turn, reduce the hot-spot temperature. Some. But don't expect a lot.

Having said all that, there are some operations where I insist on having an exit nozzle. And it's not to suck away heat from the grinding zone.

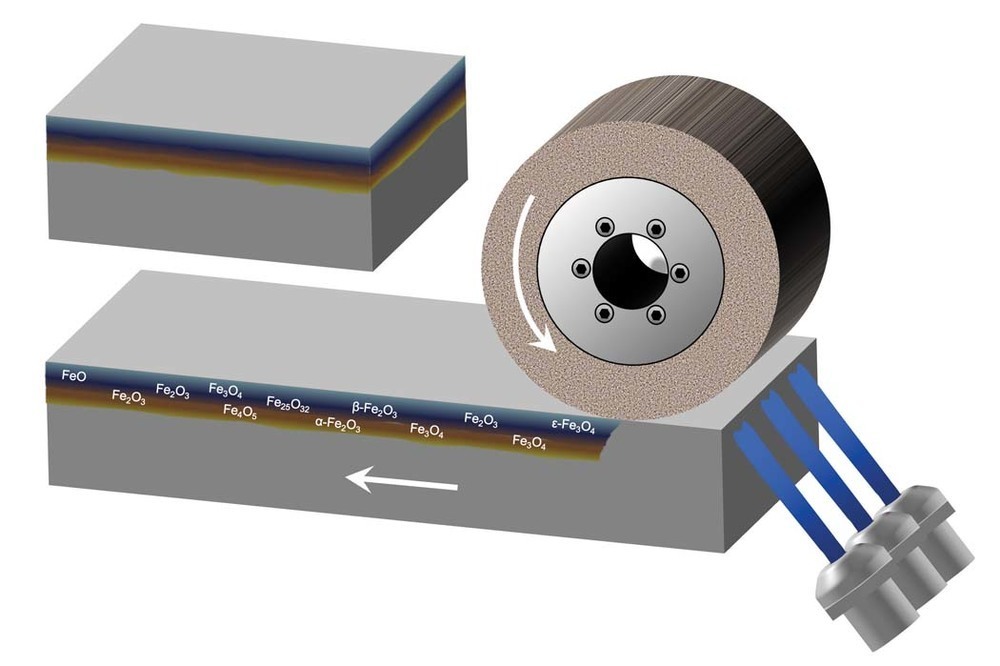

Many grinding operations suffer from oxidation burn on the unground surface. Here, grinding heat conducts away from the hot-zone to the unground surface. The iron (as steel is composed of iron-Fe and carbon-C) on that exposed surface combines with oxygen (O2) in the air to form brown, yellow and blue iron-oxides.

These oxides are very thin. (A Q-Tip with some weak acid is enough to clean it away.) The oxides don't affect the strength of the workpiece. But they don't look good. When people see brown, yellow and blue on the workpiece, they consider the workpiece burned.

Is it burned? It has oxidation burn, for sure. But does it have genuine thermal damage? (Thermal softening, residual tensile stresses and/ or rehardening burn?) The answer is: Nobody knows by looking at it. You'll have to do a test to find out.

But those brown, yellow and blue marks are unsightly. Customers don't like them. And they're damn-near impossible to eliminate. Why? Because they begin at such low temperatures. Better main-arc-of-cut cooling, sharper dressing and lower material-removal rates might reduce that oxidation burn a little, but it won't eliminate it.

Jeffrey Badger

The only way to eliminate it (or drastically reduce it) is to place a coolant nozzle directly at the oxidizing (non-ground) surface. This will do two things: it will reduce the temperature of the oxidizing surface (retarding the oxidizing reaction); and it will starve the surface of oxygen. The equation is:

Fe + O2 = FeO = oxidation burn

Fe + no O2 = no FeO = no oxidation burn

With the exit nozzle directed at the oxidizing surface, your workpiece is now a nice silver/gray color (the color of steel) and not a brown-yellow-blue color (the color of iron-oxide). Do you have genuine thermal damage? Again, you won't know unless you test for it. But your workpiece is pretty. And appearances matter.

Finally, some people say that an exit nozzle reduces burr formation.

Theoretically, that is true. A lower workpiece temperature means less workpiece ductility means less burr. But I've never seen any hardcore scientific tests to prove this, only anecdotes and opinions.