Make your first cuts count

Make your first cuts count

Get processes off to a strong start with effective, up-to-date sawing.

Before machine shops begin machining metal parts, the raw material to be used is normally cut down to size by a saw. Like machining, the sawing process goes much better when shops follow the recommendations of the firms that supply the cutting equipment — in this case, both blades and sawing machines. In recent years, manufacturers of these products have made significant upgrades to sawing technology so they can offer better performance and useful new features to customers.

When it comes to sawing raw material, shops typically have two options: doing it themselves or leaving it to a service center or processor that supplies pre-cut material, said Kent Hughes, vice president of sales and marketing at Cosen Saws International Inc. in Charlotte, North Carolina. He pointed out that some shops may feel it's more efficient to buy pre-cut material than to purchase and store uncut material and then cut it themselves. On the other hand, he said, shops that want to be in control of the process will purchase a sawing machine so they can cut material whenever they need it. He added that an in-house sawing machine is also the less expensive option in the long run and should pay for itself in three to five years, according to most customers he's spoken to.

Versatix MP bimetal bandsaw blades feature triple-tempered, high-speed M-42 cobalt steel teeth with an alloy steel backing strip. The patented tooth design reportedly dissipates stress during cutting to reduce tooth breakage and lengthen blade life. Image courtesy of L.S. Starrett

Although sawing is sometimes outsourced, an in-house sawing machine is pretty much standard equipment at shops.

"In 40 years, I cannot think of a machine shop that I've ever been in that didn't have at least one saw," said Jay Gordon, North American sales manager for saws and hand tools at The L.S. Starrett Co. in Athol, Massachusetts.

Bandsaw Basics

Saw types normally found at shops include bandsaws and circular saws. The popular bandsaw is a power saw featuring a blade consisting of a continuous band of toothed metal that runs over wheels. Hughes said circular saws offer tighter tolerances, better finishes and faster cut times than bandsaws, but these advantages come with a hefty price tag. A high-production circular saw usually costs from $125,000 to $150,000 compared with about $30,000 for an entry-level bandsaw machine for production cutting, he noted.

"A job of 10 or 20 pieces doesn't justify" a circular saw, he said. "That's going to be put under a bandsaw machine."

Bandsaws can be used to cut a variety of metal shapes, including round solids, tubing and structural members, such as beams and angles. Materials commonly cut by the machine include aluminum, steels, alloys and some exotics.

The bandsaw "is a very versatile machine," Gordon said. "It can cut just about anything."

Best Practices

Users of bandsaws can benefit in many ways by following advice from the manufacturers of the machines and blades. For example, the diameter of solid, round stock should be no more than half the maximum capacity of a saw while tubing diameters and dimensions of structural members should be no more than 70% of a saw's maximum capacity, said Ernie Torkilsen, vice president of sales and marketing at Palmgren, a maker of bandsaws in Naperville, Illinois.

"That doesn't mean you couldn't buy a 7" (178 mm) saw and cut a 7" solid diameter," he said, "but it takes a long time and you're not going to have the same accuracy as you would if you doubled up the size of the saw."

For maximum saw performance and longer blade life, Torkilsen also recommends using a blade at least 25 mm (1") wide.

Another key to successful sawing is providing the saw and blade manufacturer with specific information about the materials cut at the shop.

Bandsaws can be fully automatic like this 0.305 m × 0.305 m (1'×1') dual-column machine. Image courtesy of Palmgren

"Many times, when you ask what they're cutting, the response is, 'We're cutting steel,'" Gordon said. "Well, there's a bunch of different kinds of steel, and some cut the same, and some don't. So just the word 'steel' doesn't tell you anything." On the other hand, providing the manufacturer with the grade of the material being cut "will go a long way toward making things easier and getting better production and blade life."

In addition to knowing the specific material being cut, shops should adjust saw speeds and feeds for different materials and use the right coolant for the process. In some cases, he said misting coolants are used instead of conventional liquid coolants when sawing tubing and structural materials.

"The big advantage of that is that there is no (coolant) going down the end of the tube and onto the floor, so it's a lot less messy" than traditional liquid coolants, Gordon said. "But an argument could be made (that) it doesn't work as well either, so it's kind of a trade-off."

For recommendations on the right speeds, feeds and coolants to use for particular sawing applications, shops should check the manuals provided by equipment manufacturers. In addition, he pointed out that some manufacturers put speed and feed charts right on the machines themselves.

"All blades are going to operate the best if all the settings are correct," Gordon said.

In some cases, however, shops don't bother with suggestions from machine and blade manufacturers.

"They just put (the machine) on high, put some coolant in and try to feed as fast as they can," Torkilsen said. "Basically, bandsaws will cut without a problem, but those guys end up with shorter blade life, or sometimes they don't get as square a cut as they want."

Besides operating bandsaws according to manufacturers' recommendations, shops should perform regular maintenance. This involves taking steps to clean chips off saw blades.

"There are blade brushes that clean them off," Torkilsen said, "but people don't tend to clean."

He said, however, that those who do take the trouble to brush or blow off chips at the end of each day are rewarded with much longer blade life and much better cutting performance.

Another step that improves sawing and subsequent machining processes is making sure that operators are at least fairly well trained in the use of a saw.

In the machining industry, "most operators are entry-level and don't have a lot of training in the operation of the bandsaw machine or how to use the bandsaw blades," Hughes said. "Training operators (to use the machine and blades) is key because they're making the first cut of a part that will move throughout the shop. And the better that part is cut, the less machining you're going to have to do down the road."

Sawing Advances

Today, buyers of bandsaws also benefit from advancements that have improved both sawing machines and the blades they use. For instance, Torkilsen pointed out that the latest bandsaws cut much faster than older models thanks to improvements in commonly used bimetal blades. As the name suggests, these are made of two types of metal. A flexible spring steel is used for the blade backing while the blade teeth are milled into a high-speed steel wire welded onto the backing.

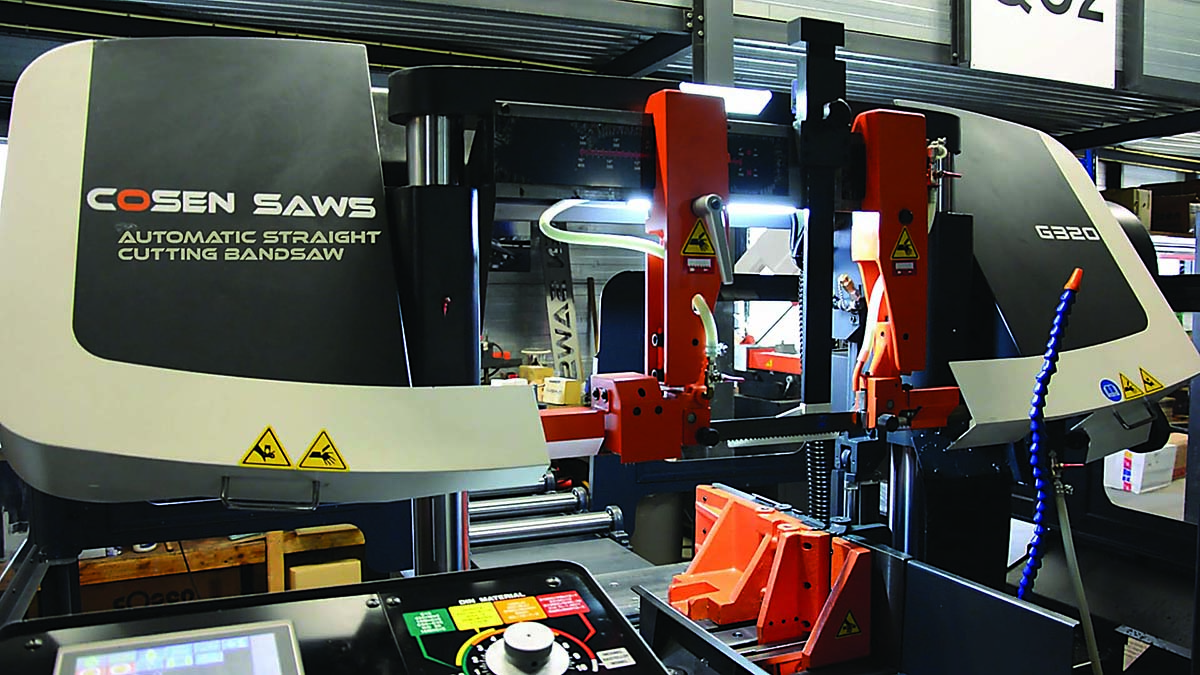

The G320 bandsaw features an inverter blade drive system that allows infinitely variable blade speeds. Image courtesy of Cosen Saws International

Although bimetal is the most popular type of blade used in the majority of applications, Hughes said more shops have been switching of late to carbide-tip blades. In some cases, he said shops have made the change because they bought a new, heavier-duty machine designed to run carbide. In others, they may need to cut materials like Inconel or stainless tool steel, applications in which carbide blades perform better than their bimetal counterparts.

In general, he said, "when you go from a bimetal blade to a carbide, you're going to be able to cut faster and the finish you get is going to be much superior. The downside is that you're going to be paying three to five times the price. So you want to make sure that your saw is in good working condition and that the operator is making the right adjustments on the machine so that blade can perform as well as it's

designed."

As for machine-related developments, Hughes pointed to technology that allows users to download speeds and feeds for specific applications from a computer. The downloaded data is based on a shop's past sawing experience.

"If the operator is not familiar with an application," he said, "you can have a speed and feed input to the saw so it's running at parameters that you found have worked the best compared to generic (ones) the manufacturer provided."

In addition, Hughes said more saws are being equipped with technology that lets users program jobs from an office. For example, a work order ticket with a bar code can be produced at an office and then taken to a saw, where an operator simply scans the code to program the saw for a particular job.

"That eliminates a lot of mistakes," he said.

Cosen Saws also has partnered with a blade manufacturer to produce a bandsaw monitoring system that includes sensors mounted onto a machine to track its performance so users can spot maintenance issues. The system monitors saw uptime as well.

Introduced in the past couple of years, Hughes said the system is being adopted more widely by bandsaw users. He added, however, that the monitoring information usually is provided to users via a web-based service they have to pay for, so the system is best suited for shops cutting larger volumes of material.

During his four decades in the industry, Gordon has seen both blade and sawing machine manufacturers turn out products capable of holding ever-tighter tolerances to satisfy ever-more-demanding customers.

"As the saw is typically the first thing to see a piece of metal, if it's wrong there, everybody's trying to make up for it as (the workpiece) goes down the line," he said. "And as (tolerance) expectations changed from 0.25" (6.35 mm) to thousandths on a 10" (254 mm) piece, manufacturers of saws and blades have had to step up their game and treat them almost like precision cutting tools."