Shop seeks to maximize machine tool investment

Shop seeks to maximize machine tool investment

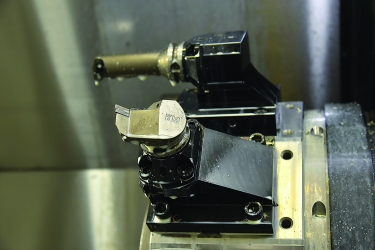

Kennametal answers with turret-adapted clamping units and quick-change toolholders.

Anthony Machine Inc. previously focused on producing medium-size parts in quantities from 10 to about 100, said Eugene Ponomarev, the machine shop's general manager and vice president. Wanting also to serve the market for small parts, the San Antonio shop purchased its first Y-axis, live-tool lathe, a DMG Mori NLX 3000 1250 turning center. After succeeding with that machine, the business bought a second one, he added.

With a priority to accomplish short lead times while offering competitive prices, Anthony Machine's manufacturing team was challenged to make the most of the new investment. The manufacturer turned to Mark Davis, senior sales engineer for Latrobe, Pennsylvania-based Kennametal Inc., who has worked with Anthony Machine for about a decade. The shop already had experience with Kennametal's KM quick-change toolholders.

Mohsen Saleh (left) and CNC Machinist Setter Mark Garland discuss a workpiece produced on one of Anthony Machine's DMG Mori NLX series universal turning centers. Image courtesy of Kennametal

"Over the years, we've built a number of KM-equipped custom toolholders for deep boring and other machining operations on our CNC lathes and machining centers, and we use Kennametal on several of the shop's manual turret lathes to overcome limitations with available tool positions," said Manufacturing Technologist Daniel Goller. "On more than one occasion, we've earned new business because KM was able to achieve tolerances and surface finishes that others couldn't do with conventional tooling."

The shop has about 20 pieces of CNC equipment, including vertical and horizontal lathes and vertical and horizontal milling machines, and employs about 25 CNC machinists, he noted.

In addition to KM toolholders, Davis explained that the best way to reduce setup times and maximize the new machines' potential would be to equip them with turret-adapted clamping units.

"He made us aware of the new units," Goller said. "Knowing the KM connection previously, he knew it was what we wanted to do."

"The TACU system supports everything from KM32 up to KM63," Davis said. "We offer blocks for both static and driven tools and can tool up lathes from Okuma, Haas, Mazak, Doosan and of course DMG Mori—pretty much all of the major machine tool builders, with more coming online all the time. This makes it both easy and cost-effective for our customers to equip more than 80 models of CNC turning centers with a fast, flexible and accurate quick-change toolholding

system."

Mohsen Saleh, operations manager for Anthony Machine, agreed.

After seeing the benefits of using KM on Anthony Machine's new NLX machines, the company plans to expand its use of quick-change tooling to other areas of the shop. Image courtesy of Kennametal

"Compared to the traditional wedge and screw-style blocks that come standard on most machines, the KM-equipped TACUs are both faster and more accurate," he said. "We routinely hold tolerances of 0.0005", and I'm told that part size doesn't change from one clamping to the next. The turret is less crowded, everything is easier to get at, and you don't have the chatter and deflection that you often find with your typical straight-shank tools and setscrew-type boring bar holders."

Goller added that the traditional block connection was cumbersome because it required a machinist to hold several different parts, mount the part and make sure everything was straight. The KM toolholders, on the other hand, have a taper and face connection that mounts with a couple of turns of a torque wrench.

"The KM connections just repeat and are always straight," Goller said. "You don't have to fight to make sure your tools are right. There is only one way to put them in. There is no misalignment like there might be with conventional tooling."

For example, if a boring bar is not aligned properly, it affects cutting geometry, which means that a machinist is more likely to have issues with chatter, Goller said.

"On the other machines, we are happy if we hit a 32 µin. Ra finish, which is not much to write home about," he said. "On the new machines, we easily hit 10 to 11 µin. Ra."

With the KM-equipped TACU system in place, Goller said Anthony Machine reduced tool setup time by about 50%.