Micromachine for max accuracy

Micromachine for max accuracy

Accurately machine EDM electrodes used to produce micromolds for medical parts. A high-speed, high-precision, 3-axis micro milling machine.

END USER: Rolenn Medical Products, (951) 682-1185, www.rolenn.com.

CHALLENGE: Accurately machine EDM electrodes used to produce micromolds for medical parts.

SOLUTION: A high-speed, high-precision, 3-axis micro milling machine.

SOLUTION PROVIDER: Microlution Inc., (773) 282-6495, www.microlution-inc.com.

As medical devices get smaller and more sophisticated, creating the molds used to shape new products becomes more of a challenge. When finished parts are measured in millionths of inches, and the devices save or sustain lives, accuracy in the manufacturing process is paramount. Accurate molds are required to make accurate parts, and accurate cutting tools and machining equipment are needed to make these molds.

Most medical-device molds are made of ultrahard metals and require EDMing to cut the mold cavity and edges to specification. To achieve the tolerances of a new mold, Rolenn Medical Products, Riverside, Calif., often needs to make its own custom EDM electrodes.

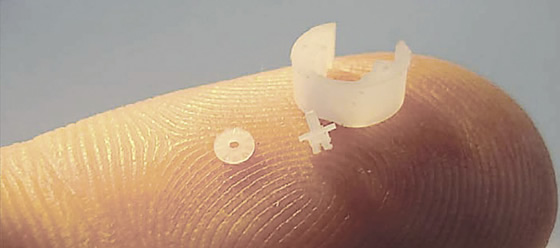

Rolenn produces small silicone parts for the medical industry (bottom) using molds created with EDM electrodes machined on its Microlution 363-S micromachine.

Ron Piotrowski, head of mold design at Rolenn, found a "go to" electrode milling solution in the Microlution 363-S from Microlution Inc., Chicago. The 3-axis micro milling machine offers micron level accuracy and tolerances, according to the machine tool builder. "Everything we do is a challenge," he said. "Making electrodes for micromolds is one of them. The 363-S has handled everything we've thrown at it."

Piotrowski found the Microlution 363-S when searching for a way to create a micromold for silicon seals that wouldn't leak. Silicon, which has about the same viscosity as water, tends to find any gap in the mold, no matter how small. It costs as much as $1,500 per pound, so leakage is costly.

"These molds must be totally accurate with parting lines that match perfectly," he explained. "The 363-S worked beautifully to create the electrodes we needed."

The machine has a positional accuracy of ±0.00004", a maximum spindle speed of 50,000 rpm or more and a working volume of 2.48" (63mm) on each axis, according to Microlution. It also features a granite base, palletized workholding, a 36-pocket toolchanger/" data-glossary-id="142091" data-glossary-teaser="Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restor…" title="Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restor…" aria-label="Glossary: toolchanger/" data-glossary-id="142091" data-glossary-teaser="Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restor…" title="Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restor…" aria-label="Glossary: automatic toolchanger">automatic toolchanger">automatic toolchanger and utilizes standard G-code programming. In addition to these features, Piotrowski found the high-acceleration capability of the linear motor-driven platform particularly attractive.

"The ways are magnetically controlled, which eliminates the need for a ballscrew, and there is absolutely no backlash, allowing measurements to be made accurately and easily," he said. "Heidenhain glass scales measure everything, and I can control it to within 0.0010 ". Also, it has enough memory for code for very complex parts."

Piotrowski added that the whole package cost about $130,000—far more palatable than the $250,000 price tag on many comparable machines the company explored.

In addition to machining electrodes, Rolenn uses the 363-S to mill some of the parts. "We've probably used this machine for more than 50 products," Piotrowski said. "It's easy to set up and reconfigure. We can drill holes 0.002" in diameter, and it goes through the material like butter. A 0.0015 " corner radius is a piece of cake."

Rolenn operates two other manufacturing facilities, but the most demanding projects are always assigned to Piotrowski's team. "People from our other facilities now send their high-precision stuff here," Piotrowski said. "There are some things that just can't be done with traditional equipment."