Mega-Multiplex

Mega-Multiplex

Heavy-duty multitask machine tools provide numerous benefits for producing large, complex components -- when the application is right.

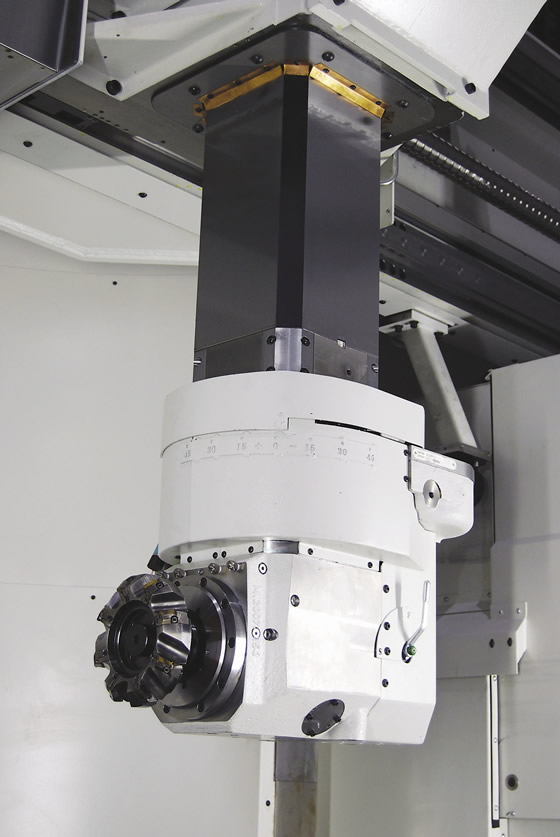

Courtesy of Starrag

The Droop+Rein high-speed, multifunction toolchanger. See automatic toolchanger." title="CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger." aria-label="Glossary: machining center">machining center from Starrag has an additional turning table and performs 5-axis machining with a fork-type head.

Heavy-duty multitask machine tools provide numerous benefits for producing large, complex components—when the application is right.

Some metalworking terms are hard to pin down: "high-performance cutting tools," "micromachining" and "high-speed metal removal" mean different things to different people. "Heavy-duty multitasking" is another elusive term.

Peter Beyer, director of product strategy and development for machine tool builder Fives Giddings & Lewis, Fond du Lac, Wis., indicated the starting point for "heavy-duty" spindle power is roughly 37 kW (50 hp). "In the minds of most people, that's a heavy-duty or high-power machine."

Workpiece size also comes into play. "We consider Giddings & Lewis to be a supplier of machine tools for large parts and we start around 1m," Beyer added.

Richard Parenteau, director of application development at Methods Machine Tools Inc., concurred that machines accommodating workpieces 1m (39.4 ") in length and longer qualify as heavy duty, as well as those with a 12 " (304.8mm) and larger chuck. The Sudbury, Mass., machine tool supplier offers, for example, the Nakamura-Tome Super NTXL multitask machine, which handles parts up to 2m (78.7 ") long and 15.5 " (393.7mm) in diameter. (See photo below.)

He placed the B-axis power requirements in the 25- to 30-hp (18.4 to 22.1 kW) range. "That's certainly more than adequate to do the kind of milling that needs to be done," Parenteau said.

Other offerings extend the workpiece size capacity, such as the Multus B750 multifunction horizontal lathe from Okuma America Corp., Charlotte, N.C. (See photo on below.) The multitask machine provides up to 6m (19.7 ') of bed length and has a maximum turning diameter of 1,050mm (41.34 ") and a 50-hp milling spindle.

"When you get into multitasking, builders typically have to make some compromises," said David Fischer, product specialist for Okuma. "The goal of the Multus was to not make those compromises. We designed it so the milling capability would be the same as one of our large horizontal milling machines and the turning would be comparable to our large turning centers."

That's achieved, in part, by starting with a heavy-duty, cross-ribbed cast iron base as the rigid foundation, Fischer explained. "You can have a very powerful milling spindle but if you don't have the iron to back it up, you create problems because you start moving the column or B-axis around."

Eye on Applications

The large parts produced in these massive machines cut across a wide swath of industries, but components for energy extraction and generation are common. They include housings for fracking pumps, wind turbine parts and valves and shafts for oilfields.

Those workpieces are often high-strength materials, such nickel-base alloys, which require a machine with high torque in the main spindle that can also impart fine surface finishes and achieve tight form tolerances, said Georg Hanrath, executive vice president of Starrag AG, Rorschacherberg, Switzerland. (Starrag USA Inc. is located in Hebron, Ky.)

One option the machine tool builder offers for meeting these requirements is its horizontal machining centers with facing heads, as well as vertical turning machines with payload capacities from 20 to 350 tons for making parts such as power generator housings, Hanrath added. "Besides the main application, turning of the assembled housings, the flanges between the housing parts must be milled and bored with high accuracy."

Courtesy of Methods Machine Tools

The Nakamura-Tome Super NTXL multitask machine handles parts up to 6.56' long and 15.5 " in diameter.

For vertically aligned arts, Fischer emphasized aerospace applications. "A lot of the aerospace parts aren't long, but they're big in diameter and can be very complex."

The type of workpiece materials also runs the gamut, but their hardness tends to peak at about 55 HRC for these large, multifunction applications, according to Parenteau.

"Large, heavy parts might be casehardened to prepare for multitask machining," said Dale Hedberg, Feeler product manager for Methods Machine Tools Inc. "However, heat treating these parts is typically not required for multitask operations."

Multitask Menu

Parenteau added that parts machined via heavy-duty multitasking are predominantly ground after heat treating, but not on the same machine. Many customers ask Methods about grinding on multitask machines. Machines that have B-axis spindles with a maximum speed from 8,000 to 12,000 rpm are capable of grinding, but he noted the machines aren't designed for the swarf that grinding generates. "That can create maintenance and warranty issues for the machine. You can do it, but we don't endorse it," he said, adding that it would require an expensive filtration system designed for grinding swarf and probably a centrifuge to remove the grinding partials. "With a proper system, we would support the machine warranty."

On the other hand, Giddings & Lewis offers a grinding attachment on its vertical lathes for customers who want to impart fine finishes without tool marks and enable size control that turning might not provide, Beyer said.

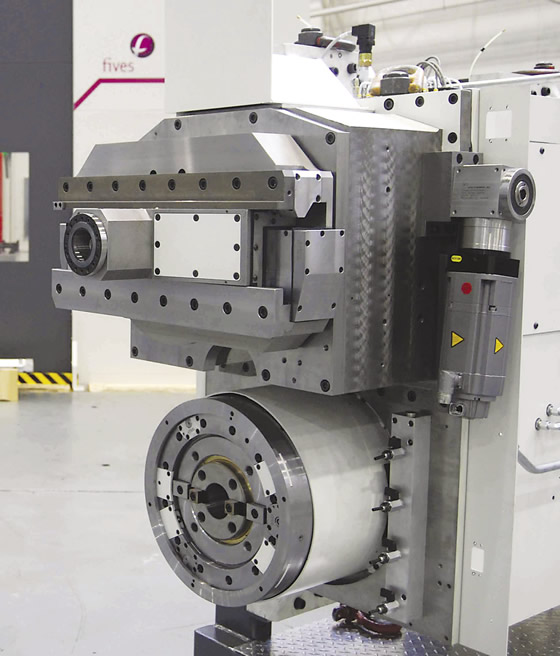

Courtesy of Fives Giddings & Lewis

Fives Giddings & Lewis' Y-axis attachment brings off-centerline turning, milling, drilling and tapping capabilities to its vertical turning centers.

In addition to grinding, as well as milling, on its multifunction vertical turning lathes, Starrag also offers polishing capabilities, Hanrath noted. Other Starrag options include grinders that can turn and drill, and machining centers with optional microforging.

Multitask machines of all sizes are commonly called mill/turn machines, but that doesn't necessarily mean the milling and turning tasks are equally divided. According to Hedberg, multitasking means primarily turning and some milling. "A few of the traditional milling machine manufacturers have tried adding turning capabilities with limited success," he said. "The greatest success is with turning centers that add milling capabilities."

Giddings & Lewis, for example, enables off-centerline turning, milling, drilling and tapping on its vertical turning centers with a Y-axis attachment that combines a C-axis head with a table and X- and Z-axis motions. "This is an affordable way to reduce setups and free up machine time on the horizontal machining centers and boring mills that used to be required to produce these same features on turned parts," Beyer said.

In addition, the machine tool builder offers an extended-range contouring head for its horizontal boring mills to produce large, turned features with a repeatability of ±0.005mm (±0.0002 ") and an accuracy of ±0.015mm (±0.0006 ").

"If the percentage of turning versus milling is small, or the part is highly unbalanced or difficult to fixture, it makes more sense to do turning operations by spinning the tool on a boring mill than by spinning the part on a lathe," Beyer explained, noting most parts produced on a multitask machine are predominantly turned or predominantly milled.

Benefits for Big

While getting a part of any size done in one setup on a multitask machine provides numerous advantages compared to producing it on multiple machines, minimizing part movement is particularly attractive for big pieces with complex features. A key benefit of heavy-duty multitasking is reducing nonproductive time due to part changeover, according to Hanrath. He noted setup times for parts weighing more than 50 tons with high accuracy requirements can consume a full shift.

Hanrath said the other main benefit is reducing part inaccuracies caused by clamping errors, because single setups permit machining features with significantly tighter feature-alignment tolerances. "Moreover, features often should be created in the orientation in which the part is later used to avoid the influence of part deformations."

Okuma's Fischer concurred that a machine operator must be highly skilled to avoid misaligning or scrapping a workpiece when moving it from machine to machine using a conventional process, and handling a large, heavy, cumbersome part multiple times creates opportunities for additional errors. "You don't want to kill a part because the operator didn't clock it properly, and setup times can be huge because you're just doing one or two parts in a lot of cases," he said, adding that machining a part in a single machine eliminates those potential problems.

Courtesy of Fives Giddings & Lewis

The integrated contouring head from Fives Giddings & Lewis enables a boring mill to turn large part features, particularly ones for the energy industry.

Methods' Parenteau emphasized that achieving geometric tolerances is a primary benefit of heavy-duty multitasking. Moving a part to a second machine might involve making a custom fixture, for example, to properly orient the part for machining a secondary feature.

"That goes away in a multitask machine because the orientation is already there," he said. "The centerline is generated—it's right on center—and the machine knows exactly where that is. From a geometric tolerancing perspective, putting that secondary feature in is very easy for the machine tool."

In addition to increasing the part's accuracy by making it in one setup, Giddings & Lewis' Beyer said a primary benefit is cost reduction when an end user buys one multitask machine instead of two or more other types of machines. Also, one machine will likely consume less floor space than two.

Take Five

Machining all the features on a large, complex part in one setup generally requires accessing all part faces, but that doesn't always mean simultaneous 5-axis capability is needed. "You want to have 5-axis capability on the machine," said Methods' Parenteau. "The control has 5-axis capability, so the machine is capable, but when you get right down to it, there are very few applications that require a true 5-axis cut. Four axes can usually do 99.9 percent of what you might think may need five."

Courtesy of Okuma America

The Multus B750 multitask horizontal lathe from Okuma America provides up to 6m (19.7 ') of bed length and has a maximum turning diameter of 1,050mm (41.34 ") and a 50-hp (37 kW) milling spindle.

Nonetheless, a machine that doesn't perform "true" 5-axis cuts can be limited compared to one that does. One example is a machine with a wedge Y-axis instead of a true Y-axis. A wedge Y-axis is the Y-axis on a turning center and is usually on top of the X-axis, requiring both axes to move simultaneously to achieve the Y-axis position, Parenteau explained. In contrast, a true Y-axis is directly 90° to the X-axis and moves independently. As a result of the compound-axes move, the wedge Y-axis machine is slightly less accurate, its speed is slower and feed is lower when performing a 5-axis cut compared to a true Y machine.

Although full 5-axis capability is available, Fischer noted Okuma typically offers 4+1 capability on its heavy-duty multitask machines because full 5-axis contouring is often not necessary. "You just need the capability to position that B-axis and do the work you need to do."

Rotary tables and 1D and 2D head attachments are available to position massive parts and expose multiples sides to the spindle for machining various surfaces. "The static and thermal accuracy, as well as the stiffness and dynamic behavior, of those attachments is a key success factor for accurate, high-performance cutting," Starrag's Hanrath said, noting the company offers rotary tables up to 12m (39.4 ') in diameter.

When designing a large multitask machine tool, Giddings & Lewis takes a modular approach. It custom configures the machine rather than custom engineering it to shorten the lead time and ensure build quality with proven, reliable components. "It's like filling your toolbox with all the right tools," Beyer explained. "The customer's particular application will dictate the correct machine travels, table size, pallet changer, work handling equipment, toolchanger, attachments and heads." He added that the flipside is buying a stock machine and living with its constraints, but it probably won't provide the best value.

In addition to OEMs, machine shops are incorporating heavy-duty multitask machines to take advantage of their flexibility and gain a competitive advantage by tackling jobs most other shops can't, Beyer noted.

Courtesy of Starrag

Doerries turning lathes from Starrag are equipped with a live spindle to enable milling and drilling.

However, Methods Machine is predominantly selling them to large OEMs for producing a specific product line or family of parts, according to Parenteau and Hedberg. Before making a hefty investment in a massive machine, a customer first has to evaluate whether it's worth it to multitask or not, Hedberg noted. This generally centers on the machine having enough horsepower and spindle speed to perform the required milling operations.

"Some manufacturers try to build so much flexibility into a machine that it's not efficient at any one thing," he said. "However, it is possible to build milling functionality into a lathe that is efficient and reliable." Hedberg provided the Feeler FVT-1000 vertical turning lathe from Methods with an all-box way design as an example.

Like heavy duty, it's a challenge to pinpoint exactly when a multitask machine tool is a good value, but machining professionals know it when they see it. CTE

Courtesy of Magna Machine

Magna Machine produces a spiral die for the plastics industry on a multiaxis Union horizontal boring and milling machine.

The 80-ton 'elephant in the room'

Machining a part on different machines might be an option for relatively small parts, but moving workpieces that weigh up to 160,000 lbs. (72,575 kg) from one machine to another is a monumental challenge.

"In a lot of cases, it takes 8 to 12 hours to get parts lined up and fixtured on the table before you even start running the program," said Scott Kramer, president of Magna Machine Co., about the massive parts the Cincinnati job shop manufactures for power generation, mining, machine tool and amusement park customers.

Courtesy of Magna Machine

Magna Machine faces, turns and mills a cylinder mold for the aerospace industry on a Bost VTL 60CY multiprocess machining center.

He's the third generation to run the company, which was founded in 1947 and has developed a niche for handling huge parts. Magna's reputation for the big stuff grew as part size increased, and the shop, which has about 120,000 sq. ft. (36,576 sq. m) of production space, purchased its first multitask, or multiprocess, machine tool in 2011 for those applications. The German-made Union PCR-160 CNC horizontal boring mill has turning capabilities, a 120-ton (108-metric-ton) capacity and a 17 "×22 " (431.8mm × 558.8mm) ram. The next year, Magna added a Spanish-made Bost VTL 60 CY traveling-table vertical turning, boring and milling machine with a 236 " (6m) swing and table extensions up to 216 " (5.5m) in diameter, and a Bost T4F horizontal turn/mill machine with a 354 " (9m) center distance and 44,000-lb. (19,958-kg) capacity. Those three machines comprise the shop's "superbay."

This year, Magna added a THC 1600 machine from Spanish builder Ibarmia Innovatek to its multiprocess equipment list. Kramer noted the mill/turn machine has a 2-cu.-m (78.7-cu.-in.) work space and a 17,600-lb. (7,983-kg) capacity and—unlike the others that enable five-sided access with 3+2 machining—provides simultaneous 5-axis machining. The capability proves beneficial, for example, when machining engine turbine casings and parts for machines that produce synthetic diamonds because of workpiece complexity and size.

The large multitask machines, as well as most of the other equipment in Magna's facility, are imported by the shop's sister company, Cincinnati-based United Precision Services Inc., which also offers machines from Machine Tool Engineering S.A. in Spain. "The sales representatives for United Precision can show and do test cuts on any of the equipment that Magna has in its facility," Kramer said. In addition, he noted Magna sometimes generates business from prospective machine buyers who visit the "large working showroom."

Kramer expects Magna's current multiprocess machines to be making chips for quite some time, and the company plans to retrofit controls and remanufacture the machines as needed to maximize machine life. "They'll be here probably as long as I will and I have at least another 20 years," he said.

—A. Richter

Contributors

Fives Giddings & Lewis

(920) 921-9400

www.fivesgroup.com

Magna Machine Co.

(513) 851-6900

www.magna-machine.com

Methods Machine Tools Inc.

(877) MMT-4CNC

www.methodsmachine.com

Okuma America Corp.

(704) 588-7000

www.okuma.com

Starrag USA Inc.

(859) 534-5201

www.starrag.com