SW North America’s twin-spindle CNC to produce tibia spacers at PMTS 2025

SW North America’s twin-spindle CNC to produce tibia spacers at PMTS 2025

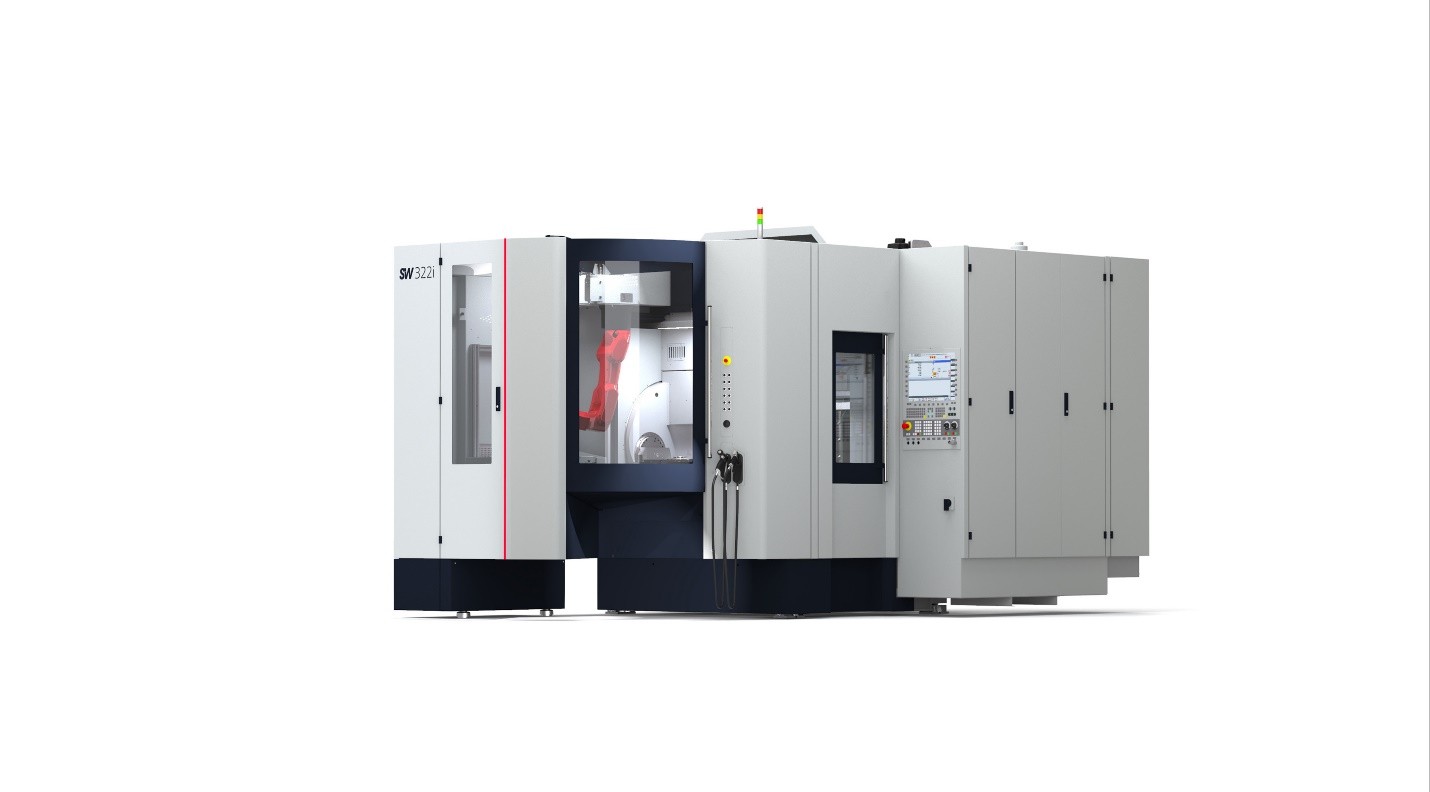

SW North America plans to conduct live demonstrations demonstration of SW North America's BA 322i, a twin-spindle horizontal CNC machining center, making tibia spacers for knee prosthetics.

SW North America plans to conduct live demonstrations demonstration of SW North America's BA 322i, a twin-spindle horizontal CNC machining center, making tibia spacers for knee prosthetics.

The demo will be on display at the Precision Machining Technology Show (PMTS) at the Huntington Convention Center of Cleveland on April 1-3, 2025.

The machining center, designed as a fully independent manufacturing cell, will be equipped with an internal Fanuc LRmate 200id 7L robot and an integrated workpiece storage unit, the BA 322i can run an entire shift with minimal human interaction.

The live machining demonstration will include the following:

- The BA 322i will produce a Tibia Spacer, a critical component in total knee prosthetics. While the live demonstration will use ABS plastic, real-world applications typically utilize PEEK, a biocompatible thermoplastic polymer that mimics the density of bone.

- The machining process includes a fully automated workflow, with raw stock loaded into the storage elevator, automated OP10 and OP20 processing, and finished parts efficiently cycled back into storage—all without manual intervention beyond loading and unloading.

- This precision-driven, high-efficiency process highlights SW's ability to enhance manufacturing capabilities for medical, automotive, aerospace, and other industries.

"At SW North America, we are committed to redefining what's possible in precision machining through automation and innovation. The BA 322i demonstrates how manufacturers can achieve higher productivity with less floor space and minimal manual intervention," said Andrew Rowley, general sales manager, SW North America. "PMTS 2025 is an opportunity for industry leaders to see firsthand how our smart manufacturing solutions can drive the right efficiency and quality that they need in today's production environments."