OPEN MIND highlights additive manufacturing capability at AM-user group expo

OPEN MIND highlights additive manufacturing capability at AM-user group expo

OPEN MIND Technologies, a developer of CAD/CAM software solutions, plans to demonstrate an additive manufacturing capability option in its hyperMILL CAD/CAM Software Suite at the Additive Manufacturing Users Group (AMUG) Exhibition.

OPEN MIND Technologies, a developer of CAD/CAM software solutions, plans to demonstrate an additive manufacturing capability option in its hyperMILL CAD/CAM Software Suite at the Additive Manufacturing Users Group (AMUG) Exhibition "AMUGexpo," Booth #38, located at Hilton Chicago in Chicago, from March 30 to April 1, 2025.

AMUGexpo is open exclusively to AMUG Education and Training Conference attendees. The AMUG conference takes place from March 30 to April 3.

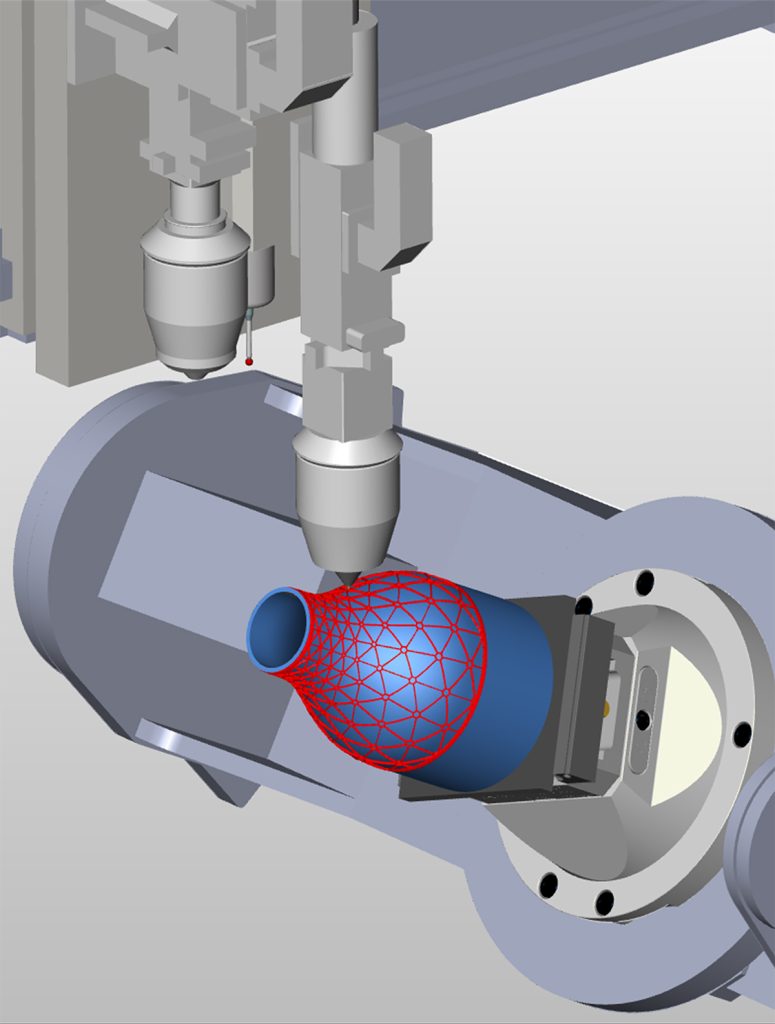

The hyperMILL ADDITIVE Manufacturing function, which supports 3D printing/additive and hybrid processes, provides efficient hybrid processing with simultaneous additive and subtractive processing on one machine.

OPEN MIND has optimized hyperMILL ADDITIVE Manufacturing technology to boost the efficiency, precision and process reliability of additive and hybrid manufacturing. At AMUGexpo, attendees can see additive part examples that were programmed and optimized with this new capability.

For highly complex 5-axis simultaneous processing, hyperMILL ADDITIVE Manufacturing enables an array of flexible options for Directed Energy Deposition processes (DED) and Wire Arc Additive Manufacturing (WAAM). Both laser-based powder nozzle machining heads and WAAM can be controlled using this feature for selective material deposition, as well as programmed and automatically simulated for collision avoidance.

Using Powder Bed Fusion (PBF) and any necessary rework, hyperMILL supports the full potential of additive manufacturing. The hyperMILL suite enables users to perfectly program cladding and milling together. True-to-detail additive and subtractive simulation as well as stock tracking between the individual process steps guarantee reliability, the company says.

Key additive applications include repair of damaged components, cladding of additional surface skins, or creation of new components from a substrate. This also creates totally new options for combining different materials, such as when high-quality material layers need to be applied to carrier materials.

A VIRTUAL Machining capability for Additive Manufacturing processes is also offered, where machines often have limited axis ranges. Now hyperMILL VIRTUAL Machining Optimizer can be used during NC code generation to simulate additive tool paths to optimize them for the machining.

For more information about hyperMILL ADDITIVE Manufacturing, click here.