Mold and die workshop with live demos scheduled for July 20

Mold and die workshop with live demos scheduled for July 20

Emuge-Franken USA, Grob Systems Inc. and Open Mind Technologies are jointly holding a complimentary mold and die workshop July 20 from 10 a.m. to 1 p.m. ET at the Emuge Technology Center in West Boylston, Mass.

Emuge-Franken USA, Grob Systems Inc. and Open Mind Technologies are jointly holding a complimentary mold and die workshop July 20 from 10 a.m. to 1 p.m. ET at the Emuge Technology Center in West Boylston, Mass.

The workshop will cover via live machining demonstrations how to optimize mold and die accuracy by combining advanced tooling, machining, and CAM technologies.

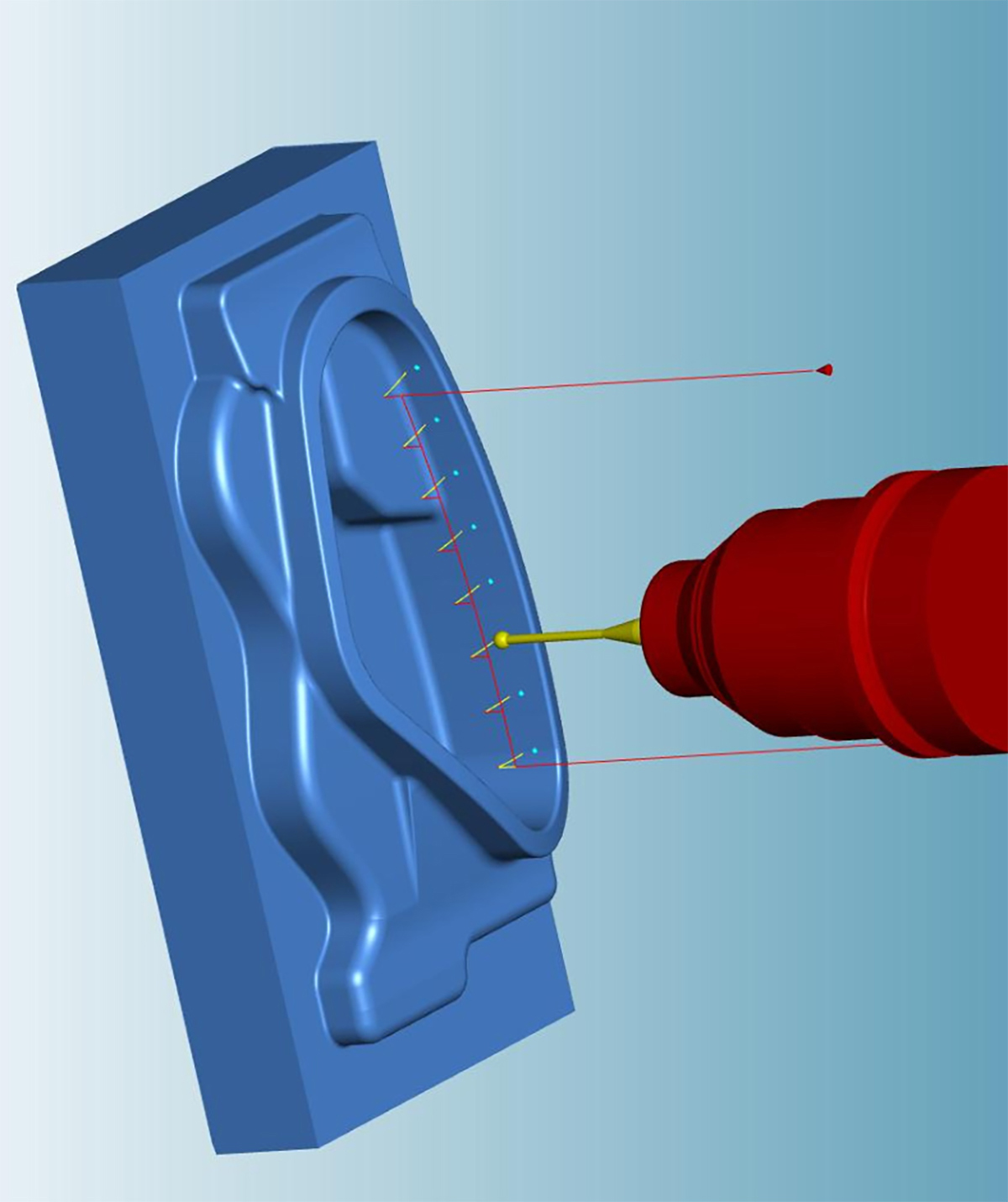

Attendees will learn how Open Mind's hyperMILL CAM software machining strategies will maximize programming for Emuge-Franken tooling on a Grob G550a 5-axis CNC machining center.

To register for the event, go to https://info.emuge.com/enhancing-accuracy-in-mold-and-die-applications.

Key workshop topics and demonstrations will include:

--Achieving high-quality surface finishes with hyperMILL's high precision surface mode by machining directly to the surface instead of an "approximated mesh," and applying the CAM software's smooth overlap capability which minimizes witness marks at the blending of adjoining part features.

--Utilizing the GROB G550a 5-Axis capabilities to properly orient and consistently maintain the Emuge-Franken Multi-Cut Duplex End Mill in the cut, while extending tool life.

--Maximizing the efficiency of the machining process with hyperMILL's auto-indexing function to automatically generate multiple 3+2 segments as an alternative to 5-Axis.

--How to use shorter, smaller diameter tools for more aggressive machining by combining GROB's rigid cross slide design and long Z-Axis stroke with hyperMILL's 5-Axis rest machining strategy, and Emuge's rigid FPC toolholder.

--Optimizing the workflow within multiple application stages by using process probing strategies.