Forest City Gear adds form grinder to expand its capacity

Forest City Gear adds form grinder to expand its capacity

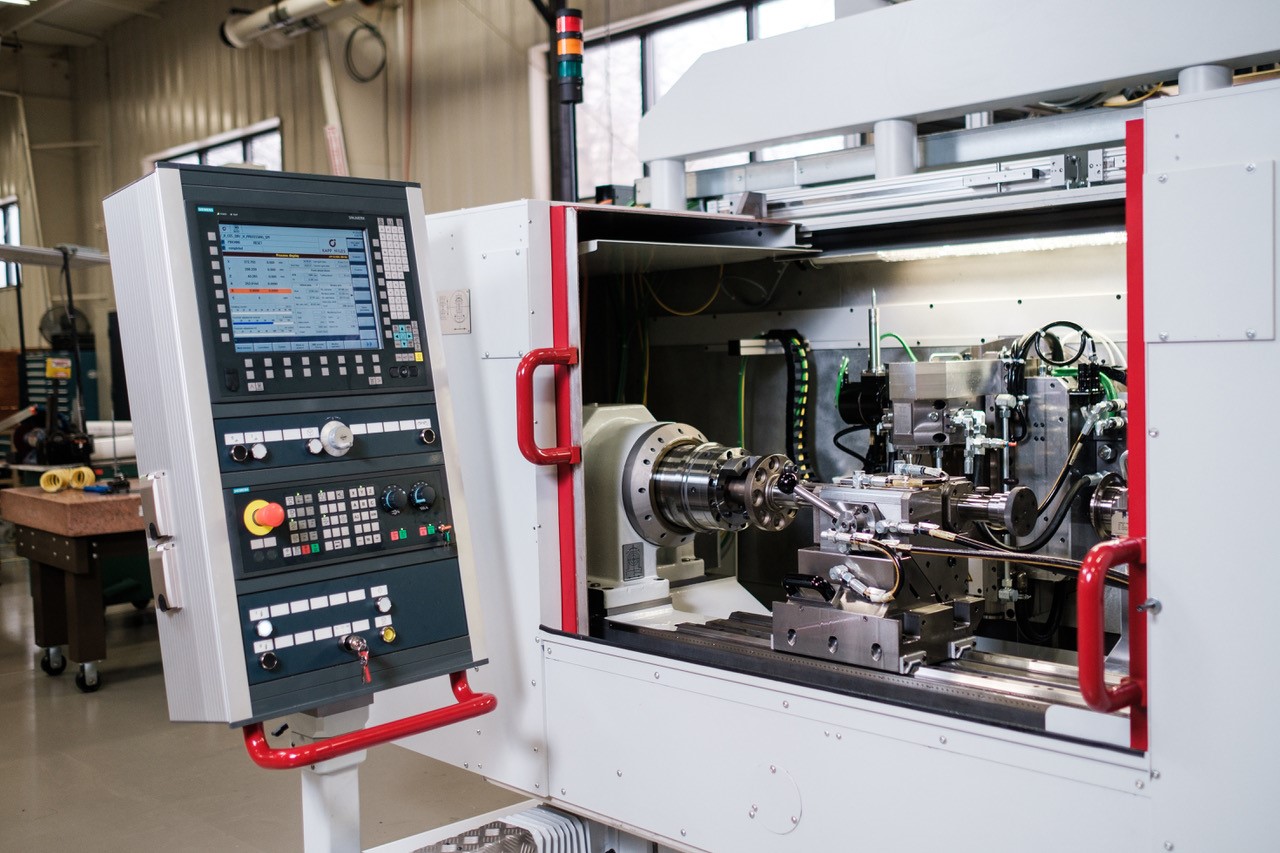

Forest City Gear has expanded its capacity for high precision finish grinding of external, internal, straight and helical gears and special profiles with the addition of its second KAPP VUS 55P form grinding machine.

Forest City Gear has expanded its capacity for high precision finish grinding of external, internal, straight and helical gears and special profiles with the addition of its second KAPP VUS 55P form grinding machine.

The new KAPP form grinder gives Forest City Gear the ability to rough and finish grind internal gears with an ID grinding diameter as small as 1.250" and external gears with an OD grinding diameter as large as 19.685". Additionally, the new machine is equipped with a high speed, 35,000-rpm external grinding spindle, so it can use smaller diameter grinding wheels to more productively grind gears positioned close to shoulders where an interference condition might exist for larger wheels.

In addition, the new machine is equipped with a specific wheel dressing unit, enabling Forest City Gear to run dressable ceramic and vitrified CBN grinding wheels for both internal and external gears to meet all types of profile requirements. The combination of on-board dressing and optional on-board measuring systems both speeds and automates the entire grinding process.

"While our first KAPP VUS 55P continues to be a dependable grinding workhorse, this new model gives us more versatility to meet the requirements of our increasingly diverse mix of high precision projects," said Forest City Gear Grinding Lead Person Kevin Chatfield. "With quality and delivery standards higher than ever across all the industries we serve, this machine is a great addition."

Since 1955, Roscoe, Illinois-based, family-owned Forest City Gear has been one of the gear industry's leading sources for the development, manufacture and inspection of high-quality gears, for use in applications that range from medical devices to motorcycles, airplanes to automation, even including the Mars Curiosity Rover.