Automating thread inspection on tubular goods

Automating thread inspection on tubular goods

According to Autonetics LLC, automated gaging units (AGUs) for threads are hot. The Cary, N.C.-based AGU manufacturer reported that it shipped 10 systems in the third quarter of last year to U.S. pipe mills that produce oil country tubular goods. No shipments occurred in the fourth quarter because the industry experienced a downturn, so capital expenditure projects got cut or delayed, noted Jeff Heath, COO of Autonetics. However, he said, the projects are starting to receive funding again. "We have about four in the build phase."

According to Autonetics LLC, automated gaging units (AGUs) for threads are hot. The Cary, N.C.-based AGU manufacturer reported that it shipped 10 systems in the third quarter of last year to U.S. pipe mills that produce oil country tubular goods. No shipments occurred in the fourth quarter because the industry experienced a downturn, so capital expenditure projects got cut or delayed, noted Jeff Heath, COO of Autonetics. However, he said, the projects are starting to receive funding again. "We have about four in the build phase."

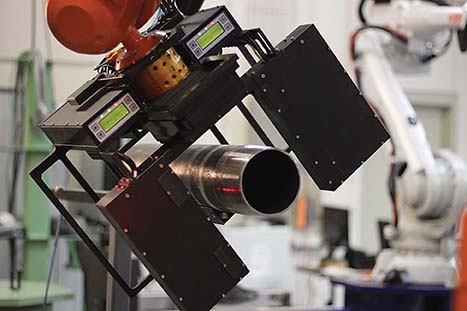

A sensor head on an automated thread gaging unit from Autonetics. Image courtesy of Autonetics.

Typically, pipe mills rely on two quality inspectors with manual gages to man a production line, one on each side of the pipe, who measure the threads of every 10th pipe, Heath explained. "It's a demanding job in a very difficult, dangerous environment," he said. "You have a 40'-long pipe that weighs hundreds of pounds clambering down the production line."

And because even the best inspector is still human, the process is error-prone, Heath added. "The manual gages are not reliable when they are put into human hands."

A thread-measurement robotic cell eliminates that human element and enables the threads to be measured on every pipe in about 30 seconds, Heath said. Each robotic cell can inspect the threads on pipes from 2 3/8" to 16" (60.3mm to 406.4mm) in diameter without impeding production.

The system records all data for every pipe in real time, which is made available to the CNC machine that performs the single-point threading operation to calculate the required tool adjustments, statistically control tool corrections and maintain acceptable tolerances, the company states. The thread-measurement data is processed and displayed as trend graphs that illustrate tool wear over time and any upstream production setup issues, such as pipe deformity or an incorrect pitch diameter.

Automatic thread measurement also allows pipe mills to validate all API (American Petroleum Institute) and premium thread callouts, letting their customers know that quality threads are an integral part of their manufacturing process. "Our clients are now able to sell the fact that they inspect every pipe—a feature that others don't provide," Heath said.

He added that premium pipe has proprietary threads that, therefore, are unique to that supplier and provide a better connection than API threads. "If you are drilling miles under the seafloor, you want to have as good a pipe as you can," Heath said, noting Autonetics must adapt its system to effectively measure premium pipe. "The dynamics of that measurement are going to be a little different than standard pipe."

Autonetics says its AGUs are customized for each client, and an AGU cell is typically located on each side of a threading line to measure thread of both sides of each pipe. The company provides up to two applications engineers on-site for up to 5 days for installation, commissioning and training. The lead time for an AGU is 24 to 32 weeks.