EDM shop finds fix with robotic automation

EDM shop finds fix with robotic automation

Dual-wire EDM automation cell helps Twin City EDM meet customer needs.

Twin City EDM and Manufacturing Inc. has been machining parts since 1959 for various industries, including defense, aerospace, aircraft and veterinary. However, the company's main focus is medical devices and components, noted Steve Lindell, vice president of the Fridley, Minnesota, shop.

"Completing difficult jobs has become our forte, especially in the medical industry," he said. "It's always rewarding to look back at the evolution of the company and how far we have come."

In addition to wire and sinker EDMing, as well as microhole popping, Twin City EDM offers five-axis and other CNC milling, laser marking and laser welding services, Lindell added.

"Because we have all the different processes," he said, "we can do just about anything."

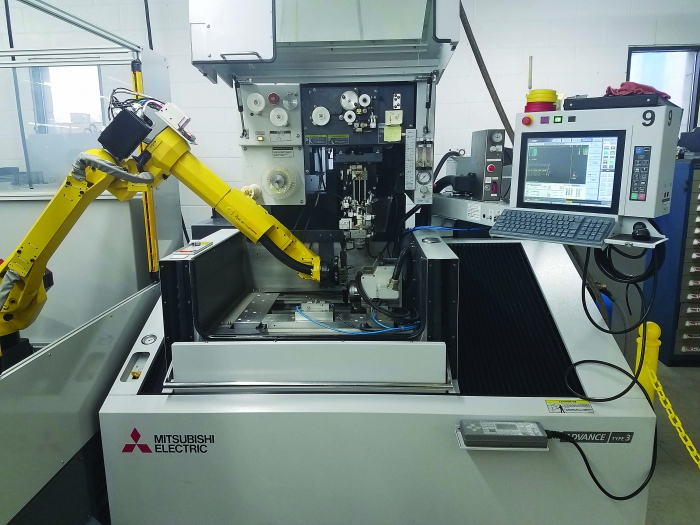

The automation cell pairs two Mitsubishi MV1200 wire EDMs with a FANUC six-axis robot for part handling. Image courtesy of Twin City EDM and Manufacturing

Lindell's father, Robert, started the company with a Charmilles sinker EDM and was one of the first to bring this technology to the Minneapolis area.

"My father is 83 and still active with the business," Lindell said. "We still have that sinker, and he still runs it."

However, Twin City EDM is now a fully stocked Mitsubishi EDM facility, with 12 sinker EDMs and 13 wire EDMs. According to Lindell, EDM operators in the area are familiar with Mitsubishi EDMs. "It's tough finding an EDM operator, but the ones who come through our doors know Mitsubishi machines over any other competitor. That is part of the reason we chose Mitsubishi."

Over the past few years, the company began to secure a number of large production orders, with some jobs having part volumes of up to 10,000 or even 20,000 parts, Lindell said. "Each year it just gets to be more production-type stuff."

To better serve customers, Twin City EDM determined that integrating a robot into wire EDM processes would be ideal for large production orders and the best investment would be a dual-wire EDM automation cell to pair two Mitsubishi MV1200 wire EDMs with a FANUC six-axis robot for part handling.

Although plenty of different machine tools lend themselves to some form of automation — Lindell said Twin City EDM has two robots for its sinker EDM side and automation for the milling machines that produce electrodes for those EDMs — it's rare to find a wire EDM with automation. That's mainly because wire EDMing often creates a slug, or leftover piece from the raw material, that needs to be manually removed from the part.

Twin City EDM purchased the new wire EDMs from Elk Grove Village, Illinois-based MC Machinery Systems Inc., a subsidiary of Mitsubishi Corp., and enlisted the services of Minneapolis-based Industrial Tool Inc., an automation robotics integrator for machine tools. ITI was able to do most of the legwork at its own facility, thus eliminating any shop disruption for Twin City EDM.

A FANUC robot tends the dual-wire EDM automation cell at Twin City EDM and Manufacturing. Image courtesy of Twin City EDM and Manufacturing

"Industrial Tool was instrumental in helping us," Lindell said.

"Like any new automation initiative, it takes time and collaboration to refine the process," said Steve Brown, regional manager for MC Machinery. "From the original discussions to full implementation, it was a yearlong process."

"After the automated cell implementation, MC Machinery's wire EDM application support team came in to optimize the setup," Lindell said. "They made a huge impact by taking out all the inefficiencies in the process. When taking a production part from a manual setup to full robot automation, the small inefficiencies in the process make huge differences in the total time."

He added that the cut times were initially about 30% slower than originally quoted, but improvements were made to bring the times to within about 5% of what Twin City EDM had anticipated. Those improvements included switching to a wire that cuts faster, positioning the upper and lower heads closer to the workpiece, enhancing flushing and generally fine-tuning the technology.

To overcome the slug issue, Twin City EDM produces relatively small, coreless parts in the cell. "We remove all the material with the wire, so there is no slug," Lindell said.

In addition to loading and unloading parts, the robot must rotate a part 90° or 45° as part of the "burn and turn" production scenario, Lindell said. "In the past, we would have to go in there and manually rotate for each view."

As a result of implementing the cell in early 2019, Twin City EDM already has seen faster turnaround times. For example, the company worked on a job that previously required four wire EDMs to complete the needed volume of parts. With the automated EDM cell, the company was able to complete the same workflow and volume with two machines.

"It was a good time to make that transition and see if we could make a go of it," Lindell said, "and it worked out."