Hold it right there

Hold it right there

Consider adding these toolholding products to your shop's arsenal.

BIG DAISHOWA

With the introduction of its C3 program, BIG DAISHOWA recently expanded its BIG CAPTO toolholder line with the introduction of its C3 program, which is designed to increase efficiency and precision for small lathes.

The C3 series of MEGA NEW BABY chucks has a clamping range of 0.010" to 0.630" with a maximum RPM of 30,000. The chucks are said to be ideal for drills, reamers, taps and finishing end mills. Ultra-slim and strong, they provide reliable gripping for even the smallest workpieces.

The BIG CAPTO C3 square holders for turning applications come in left- and right-hand orientations. The C3-180-BH16R-2058 and C3-180-BH16L-2058 mono-block holders feature insert clamps that enhance rigidity and minimize vibrations and movement during cutting.

The new square toolholders are available in 90° and 180° types. The 90° type offers a variety of orientations, including perpendicular to the workpiece. Its compact design also allows for work in spaces that are tighter or have limited clearance. The 180° type allows the tool to machine harder-to-reach areas of the workpiece.

C3 boring bar holders also are available to clamp 6 mm, 8 mm, 10 mm or 12 mm boring bars. All turning toolholders feature through-spindle coolant.

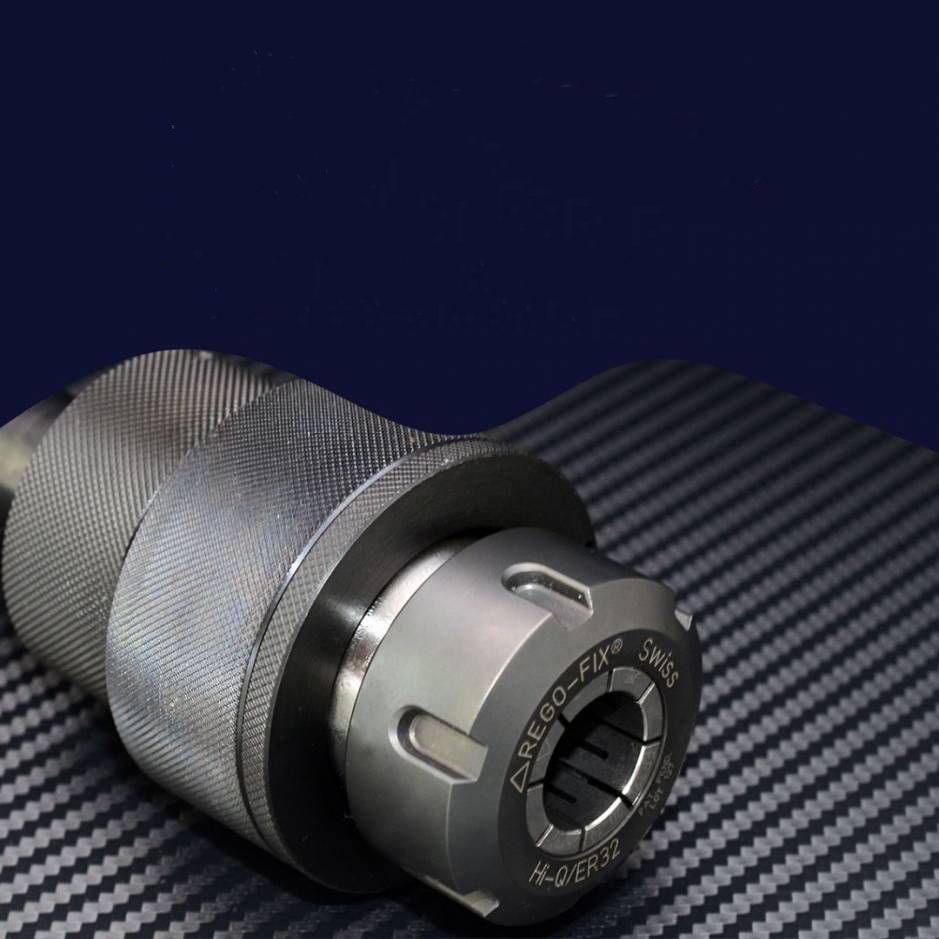

REGO FIX

REGO-FIX recently added minimum quantity lubrication (MQL) machining to its powRgrip (PG) toolholding system to help shops improve production and tool life by reducing coolant consumption and shortening cycle times.

MQL machining is a clean, sustainable manufacturing technique that directs an aerosol of compressed air and a minimal amount of cutting oil (<50 ml/h) directly to the cutting area. In addition to significantly reducing coolant consumption, MQL machining reportedly reduces cycle times anywhere from 25% to 85%, while also improving chip evacuation for better surface finish and tolerance, and increasing tool life.

The REGO-FIX standardized MQL PG collets are designed for tool shanks according to DIN 69090-3 and available for HSK-A 63 and HSK-E 40 toolholders. They are designed for machines using one-channel, internal through-spindle MQL systems and are beneficial for virtually any machining application.

In many cases, chamber and cross-section areas within a toolholding system create turbulence that causes an irregular air/coolant mix ratio in the aerosol. However, the REGO-FIX PG MQL solution uses a coolant tube fitted with a lance that directs the mixture through the collet and directly to the tool for reliable coolant distribution at the lowest consumption rate.

Ceratizit

CERATIZIT recently enhanced its new MaxiLock-N turning toolholders by incorporating the company's DirectCooling technology.

The MaxiLock-N turning toolholders incorporate two internal coolant holes that aim coolant directly at the cutting edge to prevent wear and ensure stable processes. Using these coolant holes, nozzles direct coolant to the clamping flat from above as well as from below to the flank. This additional flank cooling contributes to the tool's ability to extend tool life by 60% compared to tools that cool only at the clamping flat.

To avoid interference with workpiece contours, the lengths of DirectCooling Series holders are ideally matched to one another and offer optimal stability and unlimited flexibility. This flexibility is further enhanced with the HSK-T universal standard interface for turning tools that ensures a straightforward connection to multifunction machining centers, such as those performing both milling and turning operations.

Japan USA Precision Tools

The new Takezawa-Seiki FHN Series floating holders from Japan USA Precision Tools, Bellflower, California, are said to follow the smallest offset to improve single-pass honing accuracy and extend tool life.

Designed specifically for one-pass honing, the FHN Series method compensates for small offsets such as tilt between the center axis of the tool and the pilot hole. By correcting the offset that occurs when attaching and detaching tools with the holder, it is now possible to achieve higher precision machining, according to the company.

In honing, where very high precision is required, even small deviations between the center of the tool and the center of the pilot hole can have a significant impact on machining accuracy, quality and tool life.

Takezawa Seiki's floating holder eliminates variations in quality and load on the tool by maintaining a constant transmission torque, according to the company.

The FHN Series is available in North America by visiting this online shop: https://SocalSpecialtyTools.com. Available models include the FHNS12C1 12 mm Shank with ER20 Collet and the FHNS25C2 25 mm Shank with ER32 Collet.

T.J. Davies

T.J. Davies Co. Inc., Mantua, Ohio, produces custom retention knobs, pull bolts and other workholding components and accessories to fit older, or obsolete machinery. All dimensions of knobs can be customized, including length, diameter, thickness of collars, dimensions between collar and knob end, thread size, and more.

Additionally, customers can specify a coolant hole, taper style, and whether O-rings are required. Custom made retention knobs are sized to fit the machine tool and spindle or toolholder to maximize the toolholder's performance and cutting tool life and extend the life of existing machine tool assets.

All T.J. Davies custom retention knobs are manufactured from American-made 8620 alloy steel, which has a high tensile strength to withstand strong centrifugal force, high load force and high feed rate. All knobs are machined in-house with single point threading to Imperial (Class 2A UNC) or Metric (Class G6) standards. After threading is completed, each component is heat treated to 58-62 HRC then treated with hot black oxide to military specifications for protection against corrosion.

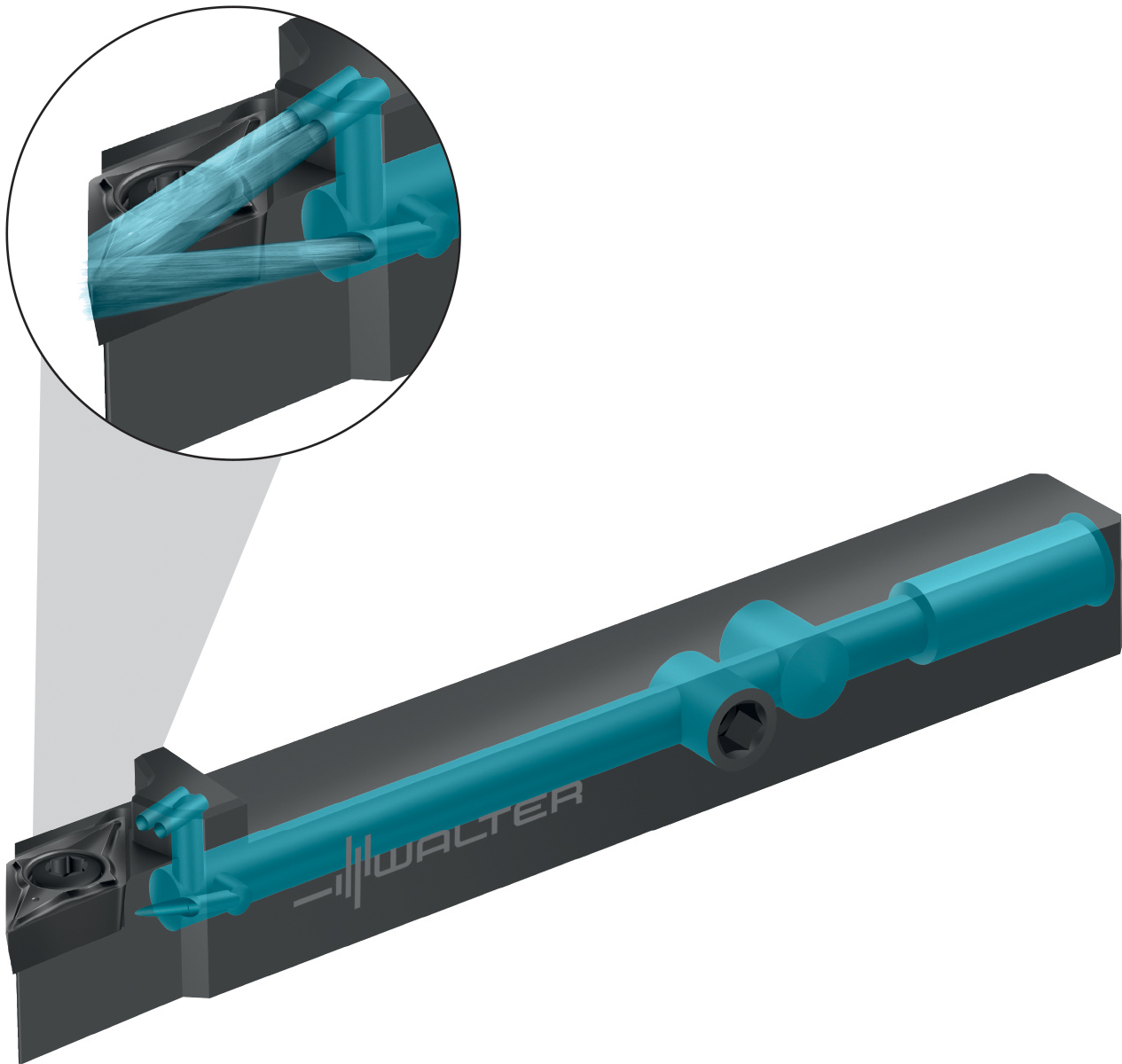

Walter USA

With its new Walter Turn Swiss toolholders for turning applications, the company is targeting applications on Swiss-style automatic lathes and multi-spindle machines that have up to 2,175 psi (150 bar) of coolant pressure. The holders are suitable for turning high-precision parts, longitudinal (axial) turning, facing and copy turning small-diameter components.

The holder provides targeted clearance face cooling for efficient chip control and increased tool life in addition to high precision cooling on the flank face to slow down insert heat and wear. The holders feature a flexible coolant connection in three positions for either external plumbing or thru-coolant introduction through lathe turrets.

The holders accept CCGT3xx, DCGT3xx and VCGT2xx indexable inserts and provide a high level of indexing accuracy even when turning parts with tight tolerance specifications. The short head dimension enables short clamping and high stability. The shank dimensions are 12 mm × 12 mm and 16 mm × 16 mm.

Potential benefits include less downtime caused by bird nesting of chips thanks to the targeted clearance face cooling and long tool life even when turning heat-resistant workpiece materials due to the cooled cutting edge.

Lyndex-Nikken

An advanced design of SK collet chucks from Lyndex-Nikken, Mundelein, Illinois, are said to optimize machine tool performance by requiring fewer collet chuck changes and improved workpiece surface finish.

The advanced design of the SK collet chuck provides increased rigidity and gripping force as well as the ability to reach tight spaces. A special heat treatment, grinding and custom slotting process enables Lyndex-Nikken to guarantee a 5 micron run-out tolerance for their "on size" fractional and metric size precision collets.

A titanium nitride (TiN) bearing nut improves rigidity as the uniquely designed gold ring reduces collet damage and micro vibration with the collet flange, according to the company. It also eliminates friction with the collet.

The taper angle provides increased gripping power as the SK collet chuck's 8-degree collet seats deeper in the body of the holder, providing double the clamping force and precision than traditional 16-degree collets. The narrow body of the SK collet chuck allows for access to tight spaces and provides better clearance making it ideal for machining complex parts.