Holding Long Overhangs

Holding Long Overhangs

When machining component features like deep pockets, long bores or intricate internal cuts, tooling setups with long overhangs are usually unavoidable.

When machining component features like deep pockets, long bores or intricate internal cuts, tooling setups with long overhangs are usually unavoidable. While essential for cutting hard-to-reach features, extended- length tools can also complicate achieving the high-quality results modern manufacturing demands.

A long tool overhang is classified by its length-to-diameter ratio. When a tool's length exceeds its diameter by more than four times (4 × D), the tool will be more prone to vibrations and deflection that can negatively impact tool life, surface quality, tolerances and productivity.

Vibrations, often audible as harmonics and chatter, can oscillate the cutting edges and leave chatter marks in the component, potentially leading to scrap. Vibrations are also detrimental to the life of the tool, which can lead to frequent tool changes and added downtime. Meanwhile, deflection — a physical bending of the tool caused by cutting forces — can lead to deviations from the intended tool path, resulting in compromised part quality or even tool breakage.

These overhang challenges are especially acute in industries like aerospace or power generation, where shops may need to work with extremely long overhangs for large component features while also contending with strict tolerances and difficult materials like HRSAs. But an increasing demand for precision, efficiency and repeatability in nearly every industry makes it essential for shops of all types to find ways to minimize vibrations and secure their long-overhang processes.

Some shops resort to make-shift solutions, like attaching lead weights to soak up vibrations or even wrapping the workpiece or tool with a garden hose. Others, more commonly, will simply reduce their cutting parameters and sacrifice productivity. While these methods may work for occasional one-off jobs, they will fall short when high-volume production is required.

Some shops resort to makeshift solutions, like attaching lead weights to soak up vibrations or even wrapping the workpiece or tool with a garden hose. Others, more commonly, will simply reduce their cutting parameters and sacrifice productivity. While these methods may work for occasional oneoff jobs, they will fall short when high-volume production is required.

Fortunately, there is a better way to tackle long overhang challenges.

By leveraging advanced toolholder technologies and strategies, shops can safely and efficiently meet the demands of machining long overhangs while achieving greater precision, repeatability and productivity at scale.

1. Minimize bad vibrations with dampened toolholders.

When it comes to tackling the excessive vibrations from long-overhang machining, anti-vibration tool adaptors can be a game changer for improving productivity. These specialized toolholders are designed with an integrated dampening device inside the tool body to minimize vibrations and increase cutting parameters.

With a dampened solution, shops can achieve a more secure and stable process to reliably meet close tolerances and attain a better surface finish. The stability also allows for much higher metal removal rates. In some cases, shops can reach cutting speeds two to three times faster than a traditional setup for long-overhang applications, dramatically improving cycle times and throughput.

Additionally, by reducing vibration-induced wear, dampened toolholders can extend tool life, lowering costs of tooling and reducing downtime related to tool changes. Although dampened toolholders may come with a higher upfront cost, their ability to improve cycle times, reduce scrap and ultimately lower costs per component make them a worthwhile investment for shops aiming to stay competitive.

The application range for dampened toolholders is also expanding, as tool providers like Sandvik Coromant continuously introduce more options for turning, milling and boring operations in a broader range of sizes. The technology is also improving. Advances in automated manufacturing have also allowed the latest generation of dampened toolholders to achieve more precise and predictable frequency areas to more effectively counter vibrations. These innovations make it easier than ever for shops to adopt dampening technology to improve the efficiency and profitability of their operations.

2. Get connected with sensor-enabled solutions.

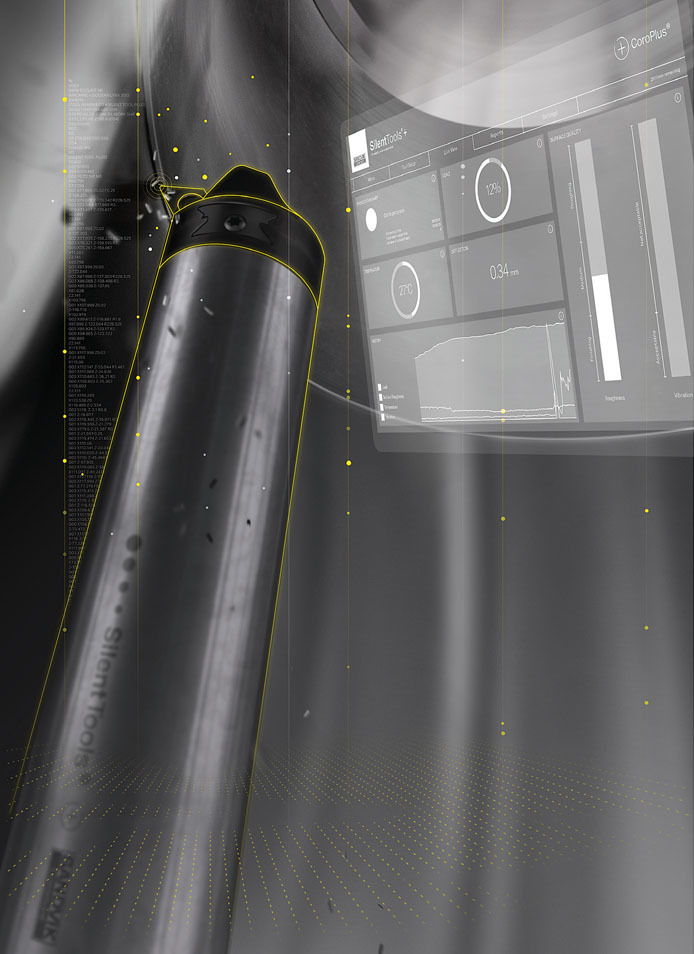

For shops on the path to digitalization, sensor-enabled solutions can offer a powerful way to take long-overhang machining to the next level. Designed to support more efficient, precise and automated operations, these Industry 4.0 tools bring connectivity and intelligence to dampened turning adapters.

For deep boring applications where the operator cannot see what's happening inside the component, sensor-integrated turning adaptors are available that can provide real-time data to tell the operator when the tool is in the cut. This connectivity enables automated monitoring of load, vibration, deflection and temperature, allowing operators to catch issues with the machining process early, before it leads to costly mistakes. Meanwhile, features like a center height indicator help streamline setups by helping operators achieve precise tool alignments. With accurate, data- driven decision making, shops can optimize processes, reduce waste and power greater automation in long-overhang applications.

To improve the accuracy and efficiency of turning adaptors that don't have integrated sensors, shops can also use attachable digital devices for streamlining setups and monitoring the health of dampened tool adaptors. Equipped with a simple magnetic attachment, the device lets operators quickly verify setup accuracy, monitor temperature and test the health of the tool.

Digital solutions like these can help unlock smarter, more reliable machining to support greater productivity for tech-driven shops.

3. Improve rigidity with the right clamping connections.

When working with dampened turning adaptors to minimize tool vibration and deflection in long-overhang machining, it's also important to consider the adaptor's connection to the spindle. Finding ways to improve rigidity in the system is essential to achieving better precision and stability.

One way to improve the rigidity of the adaptor is to install shims onto the flange, which increases the contact area with the spindle. By creating a larger contact diameter, this approach can enhance bending stiffness and helps reduce vibrations to a degree, but shims are more of a workaround rather than a comprehensive solution.

For superior results, using a dual- contact spindle system like Coromant Capto® from Sandvik Coromant, can greatly improve clamping performance. Unlike traditional setups, which rely solely on the spindle taper for support, dual-contact systems engage both the taper and the spindle face. This maximizes surface contact to significantly increase rigidity and stabilize the toolholder.

Coromant Capto achieves this by amplifying clamping force with a drawbar mechanism. And with its unique polygonal interface, the system enables rapid tool changes while also improving torque transmission, making it particularly wellsuited for high-speed, long-overhang applications.

4. Partner with a tool provider that can tailor solutions to your application.

Every long-overhang application is unique; and with so many different turning adaptors, digital tools and clamping systems available, finding the right solution to optimize performance can seem overwhelming. But shops don't need to settle for one-size-fits-all adaptors. Choosing a tool provider that can tailor products to match specific overhang requirements, precise diameters and more will help ensure shops get a precise match for their application, resulting in better performance and quality. With a bespoke tool platform, such as Sandvik Coromant's Tailor Made program, tool providers simplify the customization process with limited parameters, which leads to faster quotes, lower costs and shorter lead times than fully custom tools.

Beyond quality tools, collaborating with a full-service tooling provider can give shops access to invaluable expertise and support. The right partner can offer comprehensive support, including advice on tooling strategies, CAM software optimization, in-house machining trials and application engineering.

Facing long-overhang challenges is no small task, but with the right solutions and the right tooling partner, shops can achieve greater efficiency, precision and profitability in long-overhang operations.