How to eliminate machining saddle burrs

How to eliminate machining saddle burrs

Tired of sharp, ragged edges on holes and other part features? Get the right tool and know the proper technique for the job.

Just as holemaking is common in metalworking, so is deburring the tops and bottoms of produced holes. Chamfering tools are effective, as are the familiar Rotoburr-style scraper blades. These tools also deburr machined edges fairly well and, given the right extension or blade geometry, can access hard-to-reach areas deep inside parts. Add a few Scotch-Brite pads, a drill press and a bench grinder to the mix, and there's little that any skilled machine operator can't deburr.

However, these traditional deburring methods are slow. Features that can't be reached while in a machine — which is often much of a part — must be manually scraped, buffed and chamfered. If an operator isn't paying attention, a machine tool might sit idly while he or she is busy deburring parts. And a bit too much pressure with a grinding wheel or blade could mean the inadvertent scrapping of a completed, possibly very expensive machined component.

Worker health and safety are also a consideration. As machinists would attest, cuts, scrapes and repetitive stress injuries are common during manual deburring, never mind the potential inhalation of abrasive grit. Surely safer, more productive methods are available?

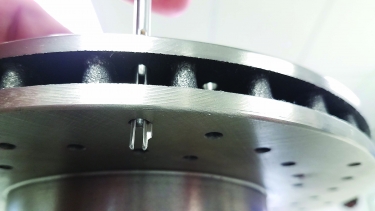

The ability to deburr both sides of a hole (above) in a single operation is a huge timesaver. Image courtesy of Whitney Tool

Two for One

"You don't want to pay CNC machinists to deburr holes," said Samuel Dean, director of sales and marketing at Whitney Tool Co. Inc., Bedford, Indiana. "You want to pay them to program and set up and maintain machinery, which means that the deburring — or as much of it as possible — is done inside the toolchanger. See toolchanger/" data-glossary-id="142091" data-glossary-teaser="Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restor…" title="Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restor…" aria-label="Glossary: automatic toolchanger">automatic toolchanger." title="CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger." aria-label="Glossary: machining center">machining center where consistency is assured and there's no chance of missing a hole. This is why it's so important to convert manual deburring operations into automated ones so that shops can more efficiently utilize their production floor staff."

One step in this conversion process is the use of Burr-Zit and Handi-Burr deburring systems from Whitney Tool, he said. Often referred to as clothespin tools, Burr-Zit deburrs the front and back of hole diameters from 1.98 mm to 25.4 mm (0.078" to 1") in a single in-and-out pass. The Handi-Burr line of spring-loaded deburring tools extends that diameter range to 50.8 mm (2"). Multiple lengths, geometries and coatings are available, and the Burr-Zit series can be purchased in kit form to cover a range of hole sizes.

Dean said Handi-Burr typically is reserved for manual deburring operations in a drill press or power tool while Burr-Zit is suitable for CNC and manual equipment. He also said both tool types are only for deburring, in that they produce a rounded edge. If a qualified, dimensionally accurate chamfer is needed, it should be machined using an actual milling cutter.

Deburring in a Snap

Matt Baumet, technical sales engineer at Heule Tool Corp., Loveland, Ohio, suggested several similar alternatives. The company's Snap front and back chamfering tools, for example, feature a replaceable, spring-loaded blade and are intended for use with CNC machine tools while providing more accurate chamfering than tools for only

deburring.

"It depends on the hole size and material," he said, "but you could expect to hold plus or minus a couple thousandths on a chamfer."

Also available are the Cofa "universal deburring tool" for elliptical or contoured surfaces, the Defa adjustable chamfering tool and the X versions of Snap and Cofa for deburring cross-holes and intersecting bores.

"The Cofa and Cofa-X are specifically designed for irregular surfaces," Baumet said. "Let's say you're deburring a hole drilled on an angled surface or a cross-hole in a piece of tubing. Here, the blade actually pivots in and out of the holder for continuous engagement. You get a nice, even chamfer all around the hole instead of the football shape you'd see using a standard chamfer tool."

Here again, multiple grades, geometries, diameters and lengths are offered, and both companies provide application and programming advice to those getting started. While Dean and Baumet might not agree on which brand of deburring tools a shop should buy, they do agree that deburring is a machining process that bears lots of low-hanging fruit.

"There are still an awful lot of people out there doing it by hand," Baumet said. "Sometimes it's because that's all they know, other times because they don't want to spend the money on a dedicated deburring tool. Either way, there's plenty of room for improvement."

Using an automated deburring tool like the Cofa, tedious deburring of small parts by hand can be eliminated for maximum efficiency and burr-free parts. Image courtesy of Heule Tool

True Grit

That covers hole deburring, but what about smoothing the sharp, often ragged edges found on pockets, bosses, ribs and other machined features? Mike Shappell, senior application engineer at Norton | Saint-Gobain Abrasives, Worcester, Massachusetts, said programming the toolpaths needed for a chamfer mill or radius cutter isn't terribly difficult, eliminating some if not all manual deburring. What's more, some shops are morphing those toolpaths for use with one of the company's nonwoven, unified or convolute abrasive wheels.

"The wheels wear well, are coolant-proof, and most CNC machine tools these days have some level of cutting fluid filtration, lowering concerns over grit and contaminants getting into the way surfaces," he said. "So with that in mind, it's not a huge leap to mount a nonwoven wheel in a CNC machining center and use it for part deburring and finishing operations. Whether you're using these products in an automated environment or a manual one, however, I strongly advise that shops review their abrasive wheel and disc selections every few years because we're constantly improving both."

Let R2-D2 Do It

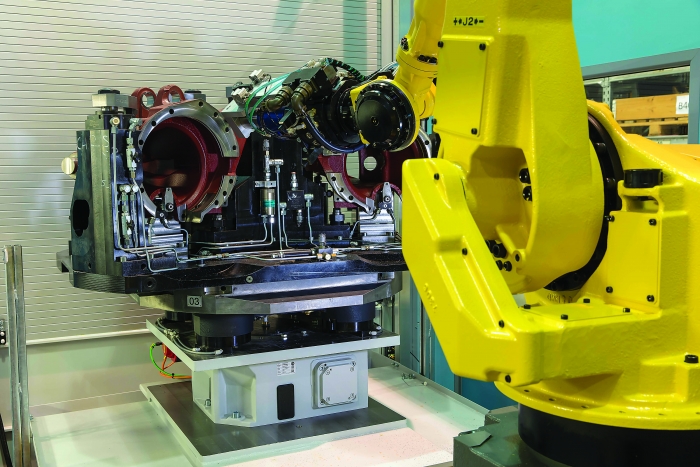

David Suica offers a novel though unsurprising approach to deburring, one that often trumps in-machine and manual processes alike. The president of automation systems provider Fastems LLC, West Chester, Ohio, said the company's self-contained robotized finishing cell comes equipped with an industrial robot and gripper system, an automatic toolchanger and a servo-powered rotary workholding table and can have electric or pneumatic spindles. The RFC is easy enough to set up that it's suitable for low-volume, high-mix work.

This self-contained robotized finishing cell boasts an industrial robot and gripper system and is suitable even for low-volume, high-mix work. Image courtesy of Fastems

"The ease of setup is largely due to our Fastsimu programming and simulation software," he said. "It allows you to import the CAD model and generate the toolpaths, the inspection points, check for collisions — all offline. There's no more standing on the shop floor with a teach controller nudging the head this way and that or trying to figure out how much wheel pressure to apply. And because there's a toolchanger and the option for a tool magazine, you can easily switch to whatever deburring tool or abrasive wheel is most appropriate for the application. There are very few parts that the RFC can't complete in a single deburring operation, with changeover often taking just a few minutes."

Although relatively new, such systems are becoming popular, Suica said. As alluded to earlier, automated deburring raises fewer health and safety issues than manual deburring. Part quality is similarly improved, with no worries over an expensive machine tool sitting idly while the operator tends to a drill press or buffing wheel. And because the robot acts as a hardworking assistant to the CNC machine tool — or flexible manufacturing system — more machine uptime is possible.

"Considering the difficulty that everyone faces in finding qualified people," he said, "plus the call for unattended machining in an environment that's increasingly demanding, the need for this level of automated deburring is clear."

Burning Burrs

Imagine a process that can completely deburr a part in less time than it took to read this sentence — much less time. The thermal energy method removes burrs, flashing and trapped particles from practically any workpiece in just a few milliseconds. TEM works by placing a workpiece — or hundreds of workpieces — in a sealed, pressurized chamber, filling it with a mixture of methane gas and oxygen and then introducing a spark. The resultant explosion generates a 3,316° C (6,000° F) heat wave that instantaneously vaporizes burrs and loose matter but leaves the workpiece undamaged.

Bruno Boutantin, global marketing director for Extrude Hone LLC, Irwin, Pennsylvania, said suitable TEM applications include die castings and machined parts of all shapes and sizes, but the approach is popular in the heavy equipment industry. This popularity is due to TEM's fast cycle times, consistency and cost-effectiveness. The method is often ideal for deburring manifolds and other large, high-volume components.

Extrude Hone also offers abrasive flow machining and electrochemical machining, he said.

The T350 and T450 (pictured) thermal deburring machines offer a fast, cost-effective way to remove burrs and loose material. Image courtesy of Extrude Hone

"AFM uses a puttylike abrasive media that is forced under pressure through or around a workpiece, removing burrs and smoothing surfaces as it passes," Boutantin said, "while ECM employs a shaped cathode and electrolytic fluid to quickly erode even stubborn burrs."

Both processes are scalable, accommodating large parts, such as crankshafts, and relatively small parts, such as turbine blades and fuel nozzles.

"They're also scalable in the sense that we have customers with multimillion-dollar equipment installations to those with fewer than 20 employees who process lot sizes of 400 to 1,000 pieces per production run," Boutantin said. "Between TEM, AFM, ECM and their variants, we have solutions for practically any deburring need."

— Kip Hanson

For more information about Extrude Hone, call 800-367-1109 or visit www.extrudehone.com.