Irregular drilling demystified

Irregular drilling demystified

Special holemaking tools and practices reduce the difficulties presented by challenging surfaces.

Drilling holes in parts becomes a bit complicated when part surfaces are irregular in some way — curved, inclined, uneven, etc. But armed with a little knowledge about the subject and the right equipment, shops can complete the task efficiently and to the satisfaction of customers.

Irregular surfaces are a fairly common feature of parts for a variety of industries, including oil and gas, aerospace and automotive, said Jamie Dunneback, North American round tool sales manager at Star SU LLC in Farmington Hills, Michigan.

"We come up against them often," he said, "but we have been very successful in developing geometries to counter the situation."

Star SU doesn't sell off-the-shelf tools for regular or irregular surfaces. Instead, the company uses CAD software to design custom tools for specific applications. To start with, the company requests part prints from customers "so we have a theoretical idea of what we're up against," Dunneback said.

When it comes to irregular surfaces, curved ones are much more difficult for tool designers to deal with than inclined surfaces, said Gary McCarel, senior application engineer at Star SU. Designers can compensate for inclined surfaces by adjusting drill point angles to make sure the point engages with the part before the corner of the drill. This is important because the drill will deflect if the corner contacts the surface before the point is fully engaged. But this is harder to prevent when a surface is curved. Designers can't always accurately predict the entry position of a drill in such cases, he explained.

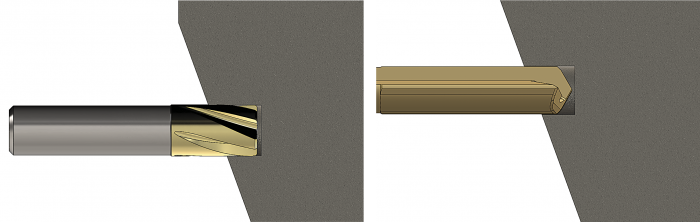

Without a spot, a flat-bottom drill can create accurate holes in curved surfaces. Image courtesy of Guhring

When entering an irregular surface like one that is curved or has a good deal of variance due to scale, a drill can "walk" because it is subjected to lateral forces, as well as the normal axial forces, said Brandon Hull, vice president of product management and business development at Guhring Inc., a tool manufacturer in Brookfield, Wisconsin. This can cause breakage, particularly if the drill is made of carbide, he said. Even in the best-case scenario, he said the result will be some deviation in hole position and diameter.

"Once that starts," he said, "the deeper you go, the more pronounced it becomes."

Hull said walking is less of a problem if the drill diameter is small compared with the diameter of the round part being drilled. This is especially true, he said, when the drill bit is stubby and has good centering characteristics like a split-point drill. Most high-performance drills have a split point, which features two additional edges ground into the chisel edge, he said.

Split-point drill bits can have four facets.

"Four-facet drill points center a little better than all the other drill points we have seen," said Manfred Lenz, product manager for holemaking and tooling systems at Seco Tools LLC in Troy, Michigan.

Start With Spotting

If a drill is large compared with the diameter of the round part, the drill will walk more than it would if the drill diameter were smaller.

"This happens quickly," Hull said, "and the drill can slip off to the side."

In this case, he recommends the use of an NC spot drill, which produces an accurately located little hole that serves as the starting point for a secondary drilling operation. NC spot drills are stubby and offer good centering characteristics, he said.

However, Hull said a spot drill works only in situations in which the hole to be drilled is right down the center of a round part. For off-center holes in round parts, he said one option is to use an endmill to produce a round, flat starting point for a subsequent drill. The flat starting surface helps keep the forces on the drill vertical rather than lateral.

Beginning a drilling process with an endmill can serve another useful purpose. Scale that builds up on a cast-iron surface during the casting process is harder than the inner material and difficult to penetrate, McCarel said. An endmill, though, can break through that scale and also create a flat area suitable for drilling on a curved or an inclined surface.

On the downside, using a spot drill or an endmill to prepare the way for drilling of irregular surfaces adds both a tool and a tool change to the process. One result is additional cycle time that may be problematic in some manufacturing situations, Dunneback said.

Featuring four facets, the new Feedmax MS drill point is suitable for aerospace applications in which centering is important. Image courtesy of Seco Tools

So instead, shops may want to consider a triple-margin drill, which has three margins per flute and a 30-degree helix.

"We have a great deal of success with it in diesel engines," McCarel said. "It cuts very straight and very quick, and it's strong enough that it doesn't always require spotting on an irregular surface."

He said the triple-margin drill works particularly well on compacted graphite, high-alloy and austempered irons.

Flat-Bottom Pluses

Another option that can eliminate the need for a spot drill for irregular surfaces is a flat-bottom drill. It can create flat-bottom holes because it has no point angle, so it is actually flat at the top. Hull said this geometry can drill accurate holes in curved or angled surfaces without a spot.

Flat-bottom drills "create their own flat to drill into the part, helping them stay on center," he explained.

In these cases, however, the drill needs to be short because side deflection will increase as drill length increases. To drill deeper holes on irregular surfaces, Hull said shops can start the process by drilling a pilot hole with a flat-bottom drill, which will leave a round, flat surface for a standard drill to finish the job.

He reports that flat-bottom drills are becoming a more popular choice for paving the way for deeper drilling on irregular surfaces. As for why, he points out that endmills used for this type of work are offered only in certain fractional sizes, such as 3.175 mm (0.125") and 6.35 mm (0.25").

Endmills "don't give you the exact diameter you need for in-between drilling sizes," Hull said. As a result, "you often have to do a circular interpolation to get the correct diameter to properly pilot a drill. So a lot of people are moving to flat-bottom drills that can give them the specific diameter they need for a hole."

In addition to flat-bottom drills being a faster, more accurate option for creating pilot holes in many cases, it's become easier to find the right drill for a specific application.

An endmill can be used to spot an irregular surface and prepare it for a subsequent drilling operation (left). Once the endmill has created a pilot hole, the drill has a flat surface to enter (right). Image courtesy of Star SU

"I think because of all the potential sizes a customer may need, there weren't a lot of off-the-shelf flat-bottom drill options" in the past, Hull said. "But in the last five years, we have started to see companies come out with standard offerings you can pick out of a catalog on a more regular basis."

A variation of the flat-bottom drill designed to be helpful on irregular surfaces is Seco Tools' Feedmax SD245A. Lenz describes this solid-carbide tool as "partially a flat-bottom drill" because the drill point is flat except for a very small 140-degree tip in the center. The SD245A also features four land margins — cylindrical shapes ground near the cutting edge for guiding purposes — as opposed to just two on standard drills. Two land margins aren't enough to guide a drill on an irregular surface, "so it's going to walk, and it's going to break," he said.

He reports that users have found the SD245A design to be particularly beneficial when exiting holes with irregular surfaces.

"People are usually breaking drills coming out of an irregular exit," Lenz said. "But we put this drill in there, and it solves the problem."

System Considerations

McCarel said if a tool deflects when entering an irregular surface so that it is not parallel to the axis of rotation, the tool will break.

"So entry conditions on these surfaces are extremely critical," he said.

In almost all situations involving irregular surfaces, McCarel recommends reducing the drill feed rate on entry to 40% to 50% of the normal feed rate until the margins are fully engaged, which normally occurs at a depth of up to twice the drill diameter. But during this "soft start," drill speed is not reduced.

"You have to run at the rpm recommended for the application to have the angular momentum required to shear the material," he explained.

To minimize drill deflection, Hull suggests dropping the feed rate by 50% to 75% compared with the program feed rate when entering and exiting an irregular surface. For the same reason, he recommends that the entire drilling system — including the fixturing, toolholder and machine — be as rigid as possible. Instead of an ER32 collet that gives, for example, a hydraulic or shrink chuck would be a better choice of toolholder in these cases.

As for the machine, "this means the gibs and ways are all nice and tight, so there is not going to be any movement while you are drilling," he said. This can be true of new machines, as well as older machines that have been maintained well.

In fact, Hull said, "most CNC equipment today can handle any of this stuff."