Keep machines running with modular workholders

Keep machines running with modular workholders

Modular, quick-change workholders suit the requirements for low-volume, high-mix parts manufacturing.

As a job shop starts a workday, the faces and machine tools on the shop floor look familiar, but the orders that come through the door and the parts that need to be produced may not. As a result, modular, quick-change workholders are needed to reduce setup times and keep chips flying while providing rigidity, repeatability and accuracy.

"The goal is to have as much uptime as possible," said David Pynakker, facility administrator at Lang Technovation Co., adding that workholders must ensure that machinists easily can swap back and forth among various machining operations.

To enable that, the Hartland, Wisconsin-based company offers the Quick-Point zero-point clamping system as one option. Everything works off two different pull stud sizes and spacings of 52 mm and 96 mm (2.05" and 3.78") on center from pull stud to pull stud, he said.

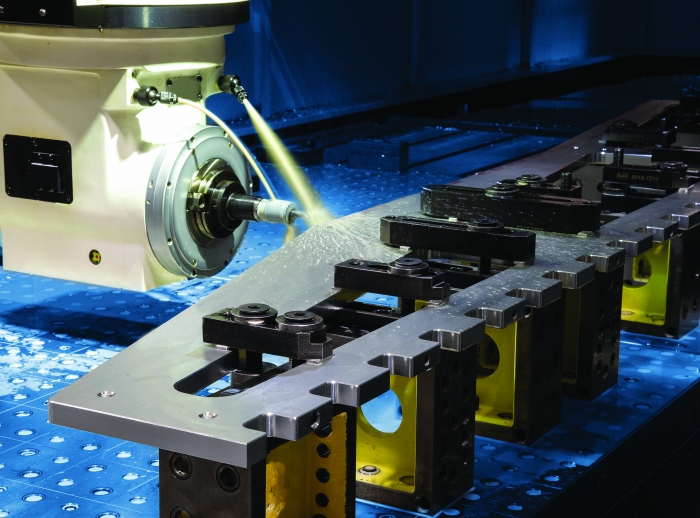

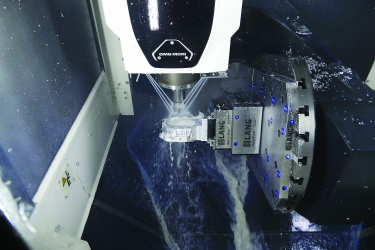

Modular workholders can be set up and rearranged quickly to handle a variety of parts. Image courtesy of Bluco

According to the company, the system can be used on vertical and horizontal machining centers, on three- and five-axis tables and with fourth-axis rotary or trunnion systems. The attachment of the zero-point plate to the machine table or faceplate is done through prefabricated hole patterns, which can be modified to fit a table, and mechanical clamping is performed via an actuation screw.

"It's a very easy-to-use system once you set up a plate on your table," Pynakker said. "With the Quick-Lock, you just have to turn the handle 180 degrees, and it locks in your fixture. Turn it back, and it unlocks so you are ready to swap in your next fixture. It's a very quick changeover when it comes to putting anything with clamping studs into it."

Having a common interface like the 52/96 system allows end users to use workholding devices, such as vises, from any workholder manufacturer that supports that system — if not directly, then through a simple adapter, said Joe Schneider, vice president of marketing for Mate Precision Technologies in Anoka, Minnesota. Launching this spring, the company's 52/96 zero-point, quick-change workholding system is a line of self-centering vises, quick-change bases and mounting systems for three-, four- and five-axis machining centers.

"Customers are willing to swap top tools," he said, "but they don't want to be swapping out the interfaces to their machines."

Schneider said another key consideration is maintaining a compact form.

"We don't want to force customers to reprogram their machines," he said. "That would be a cardinal sin to have them reprogram their machines because of a big, bulky top tool."

DynoGrip self-centering vises (left) and DynoLock quick-change bases (right) provide zero-point quality engagement with a four-post pull stud pattern. Image courtesy of Mate Precision Technologies

One characteristic of Mate Precision Technologies' new DynoLock bases is the poka-yoke alignment feature. An element of lean manufacturing, the poka-yoke feature is a way to reduce opportunities for mistakes with a mechanism that enables an operator to identify the orientation of the base of a vise so setups are repeatable by design, said Frank Baeumler, vice president of workholding.

"If you create a system that causes you to repeat the same way all the time," he said, "errors are reduced, which is the intent of (the) poka-yoke feature."

Regardless of which manufacturer makes the workholding system, Schneider said end users seek to reduce setup time through repeatability and by not having to probe a part every time.

"We have looked at it from a machinist's perspective in understanding what's impeding setup time," he said.

Clamping Head Swaps

Eliminating the need to indicate when going from one clamping head size to another is an important benefit when performing quick changeovers, said Timothy J. Wachs, president of Hainbuch America Corp. in Germantown, Wisconsin.

"They repeat within 5 to 10 microns (0.0002" to 0.0004")," he said about clamping heads using the company's quick-change system. "You don't need to re-indicate or anything. You change the size, and away you go."

Although some people refer to a clamping head as a collet, Wachs said a clamping head has three sections separated by vulcanized rubber, whereas a workholding collet is one solid piece with slits. Hainbuch America offers a fixture changer, which is a hand-held installation gun, to change a head in seconds from one diameter to another.

"We invented the clamping head," he said.

To change a clamping head, Wachs said the company's installation gun is needed.

Pulling the trigger releases the clamping head from the chuck and enables an end user to change to a new diameter "in a matter of seconds," he said.

In addition, Hainbuch America offers quick-change adaptations for its chucks. So instead of clamping on a part's OD, an ID mandrel allows a user to change bushings to different sizes to hold a part's ID, Wachs said.

To hold large parts in a chuck up to 304.8 mm (12"), the company developed the centroteX quick-change chuck system. He said the system permits changing a chuck in 10 to 15 minutes compared with the hours that might be needed to change a chuck conventionally.

"We put a flange plate that goes onto the spindle and then quick-connects to all the other plates," Wachs said, "and you can put anybody's chuck on that flange plate."

Automation Trends

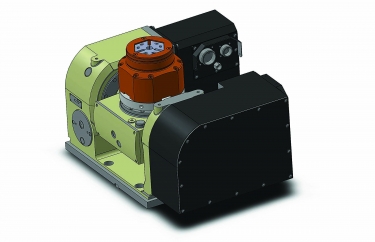

He said Hainbuch America's latest development is the centroteX S clamping device changeover system, a miniature version of the technology. Actuation takes place with one cap head screw to further minimize setup time.

"We've automated it so you can change out a whole chuck with a robot," Wachs said, "being able to change over robotically lights out to keep moving with different part numbers and different part families."

Automating quick-change workholding typically requires a significant initial investment, but the productivity gains can provide a quick payback. Pynakker said Lang Technovation offers a robot-based cart system to continuously change carts while swapping jobs.

From left to right are a TOPlus chuck with a clamping head, a two-jaw module, a Mando Adapt ID mandrel, a Morse taper workholder, two views of a three-jaw module and a face driver. Image courtesy of Hainbuch America

"It's not a pallet-changing system," he said. "It allows up to 84 parts to be placed on two carts. Even shops that don't have a lot of space can get 168 vises for smaller parts in a four-cart system that can be modified to fit your available area and installed within four weeks via Gamache Systems."

Gamache Systems in New Berlin, Wisconsin, provides CNC machine tending automation.

Pynakker said Lang Technovation's first U.S. customer for the cart system purchased a second system within a few months of the initial purchase and bought a third by the time the second was installed.

"Automation is a great answer to those shops needing a small footprint, high volume and increasing return on investment," he said, "especially for lights-out machining."

Schneider said pallet systems are one of the most common types of automation being employed for workholding.

"Pallet systems have been the first place people start when they pursue automation in this space," he said.

Baeumler said a key element in an automated system is a mechanism that performs "the handshake" between the vise and base, or object No. 1 and object No. 2, to ensure they can communicate with each other.

"There is an adapter that goes between object one and two to make those two talk to each other," he said.

More on Modular

Bluco Corp. is another manufacturer of modular, quick-change workholding. With more than 30 years in the modular fixturing industry, the Naperville, Illinois-based company has evolved a novel approach to fixturing that invites customers to consider more than components and base plates, said Director of Sales Brian Dodsworth.

"Modular fixturing as a category is not new," he said. "It functions like it always has and offers the same set of benefits that it always has. But the way Bluco approaches the design of a solution is very new to most manufacturers. We don't start with an order form — we start with the challenge our customer is trying to solve."

The process begins when a customer shares CAD files of its part or parts via Bluco's website.

"That CAD file, along with the customer's input around what goals they're trying to achieve, is where the fixture design begins," Dodsworth said.

Five-axis machining is shown with a standard 96 mm setup in which a part is held in a vise on top of a riser mounted to a plate. Image courtesy of Lang Technovation

Bluco then is able to customize a workholding system, drawing from more than 350 modular components available in two sizes.

This approach is supported by Bluco's in-house staff of application engineers, on-site manufacturing facilities and Validation Center, which allows customers to try before they buy, Dodsworth said. For manufacturers that specialize in low-volume, high-mix work, including job shops, research and development facilities and even OEM operations producing short runs of a family of parts, the process allows them to tap into expertise that may not be available in-house. The result is increased efficiency and final part quality that otherwise would be difficult to achieve.

"In the end," he said, "this approach delivers a solution that solves an immediate problem and also provides building blocks that can solve future problems."

Of course, modular fixturing continues to offer the timesaving and space-saving benefits it always has when compared with other options: dedicated fixtures or manual setup of an in-house-produced fixture. Although using a dedicated workholder that's already built provides fast changeover, use is limited to one part, and storage can be a problem, Dodsworth said. Homemade fixtures can be both time-consuming to build and difficult to store.

"Modular," he said, "on the other hand, checks all the boxes for efficiency, repeatability, ease of storage and ROI."

According to Bluco, a modular system provides an ROI in eight to 10 fixtures.

"That's a good rule of thumb," Dodsworth said. "We've seen ROI in the first couple of months if they're doing a lot of work and coming from a manual setup. That alone makes modular a slam dunk."

To expand the range of applications for modular workholders, Bluco's line of extra-large modular fixturing is in beta pre-launch, with a market introduction planned for the near future. The company reports that this will be its third complete line of modular fixturing for machining and that this joins the full family of modular offerings, which also includes welding solutions.

Dodsworth said Bluco wants to change the way manufacturers think about modular fixturing.

"Modular can be about more than just flexibility and efficiency," he said. "There is a level of support available that can change a customer's whole manufacturing process for the better."

Regardless of the workholding technology, "every user wants the convenience of knowing that whatever they are using isn't going to box them into a corner," Baeumler said. "They want to have freedom to maximize what they're trying to accomplish. Being flexible and having choices is attractive from the user point of view."

For more about modular, quick-change workholders, view presentations by Bluco, Hainbuch America and Lang Technovation at www.ctemag.com by scanning the QR code with your smartphone or entering this URL on your web browser: cteplus.delivr.com/2mxqg

Setting the Table

Part manufacturers seek to reduce the number of operations a machine tool performs while minimizing the number of machines needed to complete a part. That scenario is achieved by adding a rotary table, said Andrew J. Esposito, national sales manager for Koma Precision Inc.

For example, adding a fourth-axis rotary table to a vertical machining center might enable an end user to complete a part in three operations on one machine.

"You have one cycle start that can run through an entire complete part," Esposito said. "Without the table, you have six, seven or maybe eight, depending on how your positions need to be, and maybe four or five machines to do it."

Koma Precision says the TWA-160 tilting rotary table offers high speed and accuracy. Image courtesy of Koma Precision

The East Windsor, Connecticut-based company offers Tsudakoma four-axis rotary tables for VMCs, fifth-axis tables for horizontal machining centers and fourth/fifth-axis tables for VMCs.

"We make a wide variety of table sizes to fit a wide variety of machine tools," Esposito said, "everything from a tiny BT 20 drill/tap machine up to (a) large boring mill."

He said a key point to incorporating a rotary table is control limitations, which depend on the CNC chosen by the machine tool builder.

By machining a workpiece in one fixture, such as a pneumatic vise or a zero-point palletized clamping system, a rotary table allows manufacturers to increase throughput and part accuracy — the biggest advantage.

"You are not worrying about how the part aligns vise to vise," Esposito said. "You are always looking to do it as accurately as possible and then as quickly as possible."

Palletizing parts is another option for workholding on a rotary table. He said Koma Precision's RTT series tables are a popular choice for VMCs because they come standard with built-in rotary joints for use with a pallet system. A robot can be incorporated to load and unload parts for low-volume, high-mix environments.

"Palletize them and probe them to figure out what part is on the table," Esposito said.

He said a programmable logic controller often is used to control the robot, as well as to clamp and unclamp any workholding on a rotary table.

"That way," Esposito said, "the robot can pick and move parts around and control where those parts go in the process. It also controls the running of the machine tool and the programs on the machine tool. Even when users don't initially plan to employ automated workholding, they frequently preemptively provide for the robotic portion when purchasing a machine tool and rotary table to future-proof the process."

He said the goal when adding a rotary table ultimately is to increase spindle run time by decreasing setup times and thereby boosting profitability.

"Achieving that objective enables part manufacturers to have one operator run multiple machines and not have to hire the elusive skilled worker to meet any rise in demand for parts," Esposito said. "If you have a shop of 20 people and can have them run more machines, you get more throughput with the same overhead costs."

For more information about Koma Precision, call 800-249-5662 or visit www.komaprecision.com.

— Alan Richter